Detailed Design Guide for Steel Structure Factory Buildings: The Pillar of Modern Industrial Architecture

With the acceleration of industrialization and the continuous development of construction technology, стальная конструкция factory buildings have become the mainstream choice in the industrial building field due to their unique advantages. Compared with traditional concrete structures, steel structure factory buildings excel in construction cycle, space utilization, and environmental performance, gradually changing the face of industrial buildings.

Design Advantages: Why Choose Steel Structures?

The design of steel structure factory buildings offers multiple advantages. First, steel’s high strength and light weight allow for large-span spaces, providing great flexibility for the layout of production equipment. Second, steel structural components can be prefabricated in factories and installed on-site, significantly shortening the construction cycle and reducing the impact on the site environment. Furthermore, steel is recyclable, conforming to the concept of sustainable development, and has excellent seismic performance, making it particularly suitable for earthquake-prone areas.

Wang Ming, a senior engineer at an architectural design institute, stated, “Steel structure factory building design not only focuses on the building itself but also emphasizes its compatibility with the production process. Many of our designed factory buildings achieve high coordination between the column grid layout and production line height, significantly improving space utilization.”

Design Key Points Analysis

- Load Calculation and Structural Selection

The design of a steel structure factory building begins with accurate calculation of various loads, including permanent loads (structural self-weight), variable loads (equipment, materials, personnel), wind loads, snow loads, and seismic effects. Based on factors such as the factory’s purpose, span, and height, different forms such as portal steel frames, frame structures, or truss structures are rationally selected.

- Main Frame Design

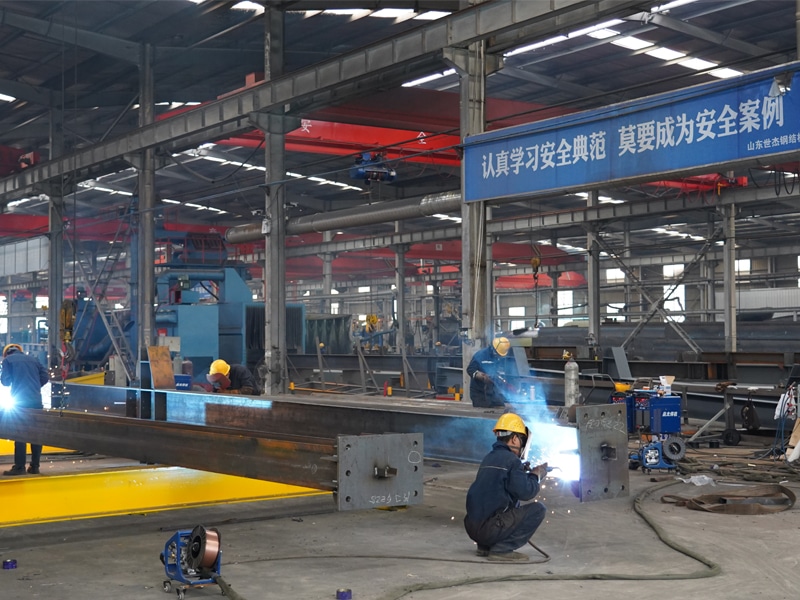

The main frame is the “skeleton” of the steel structure, including steel columns, steel beams, and connection nodes. The design must comprehensively consider the rationality of stress distribution, economy, and ease of construction. Currently, H-beams are widely used as the main load-bearing components due to their excellent cross-sectional properties and good load-bearing performance.

- Enclosure System Design

The wall and roof enclosure systems directly affect the factory’s functionality and energy consumption. Modern steel structure factory buildings mostly utilize colored profiled steel sheets or sandwich panels, offering excellent thermal insulation, heat insulation, and waterproofing performance. Special attention must be paid to the airtightness and watertightness of connection nodes during design.

- Wind and Seismic Resistance Design

Given the diverse climate and geological conditions of different regions in my country, steel structure factory buildings require specialized wind and seismic resistance designs. Measures such as installing support systems, rationally arranging wind-resistant columns, and strengthening node connections ensure the structural safety under extreme weather and seismic loads.

Technological Innovation: Intelligent and Green Development

With the widespread adoption of BIM (Building Information Modeling) technology, steel structure factory building design has entered a new digital phase. Design teams can perform clash detection, construction simulation, and quantity surveying in a 3D environment, significantly reducing design errors and on-site changes.

Simultaneously, green building design concepts have deeply penetrated the field of steel structure factory building design. The application of energy-saving technologies such as integrated photovoltaic roofs, natural ventilation systems, and rainwater harvesting systems ensures that modern steel structure factory buildings not only meet production needs but also become important carriers of sustainable development.

Detailed Design Process

A typical steel structure factory design process includes: preliminary planning → schematic design → preliminary design → construction drawing design → detailed design. The detailed design stage requires close collaboration with the manufacturer to transform the design drawings into detailed drawings of workable components, a crucial step in ensuring project quality.

“Modern steel structure factory design increasingly emphasizes a full life-cycle approach,” points out Li Hua, design director of a well-known domestic steel structure company. “From the initial design stage, we consider manufacturing, installation, use, maintenance, and even future renovation possibilities, requiring the design team to possess interdisciplinary comprehensive capabilities.”

Looking to the Future

With the continuous emergence of new materials and technologies, стальная конструкция factory design is developing towards greater efficiency, intelligence, and environmental friendliness. The promotion of prefabricated building technology will further shorten construction periods, the application of intelligent monitoring systems will improve factory operation and management, and modular design concepts will make factory expansion and functional adjustments more flexible.

As an important component of modern industry, the improvement of steel structure factory design directly relates to the competitiveness and sustainable development capabilities of my country’s manufacturing industry. In the future, with the improvement of industry standards and the innovation of design concepts, steel structure factory buildings will undoubtedly play an even more important role in the field of industrial buildings.

ПОЧЕМУ ВЫБИРАЮТ sdshijie

Изготовление металлоконструкций на заказ — наша специальность

Еще проекты