Combien coûte la construction d'un entrepôt industriel à structure métallique ?

Building a steel-structure industrial warehouse is a significant investment. It offers durability, flexibility, and cost-effectiveness.

Understanding the costs involved is crucial for planning. These costs can vary widely based on several factors.

Location, size, and design complexity all play a role in determining the final price.

Steel construction costs typically range from $15 to $25 per square foot. Custom features can increase this to $40 or more.

This guide will provide a detailed warehouse cost breakdown. It will help you make informed decisions for your project.

Why Choose a Steel-Structure Warehouse?

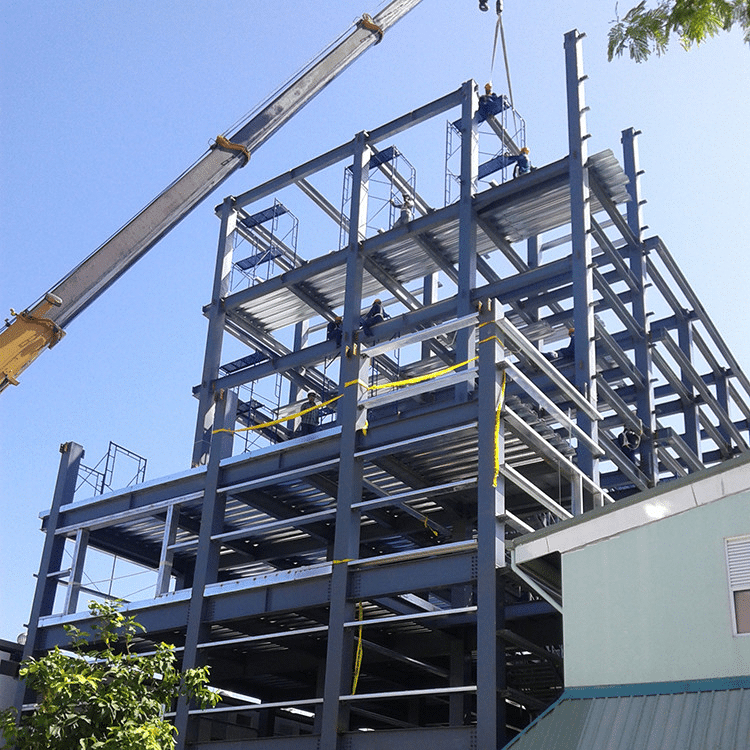

Steel-structure warehouses are a favored choice for many due to their multiple benefits. They offer exceptional durability, making them long-lasting with minimal maintenance.

Additionally, steel buildings provide great design flexibility, allowing for easy future expansion or modifications. This can be particularly advantageous for growing businesses.

Here are some key benefits of choosing a steel-structure warehouse:

- Durability: Resistant to pests, fire, and extreme weather.

- Cost-effectiveness: Lower long-term maintenance costs.

- Design Flexibility: Easily customizable and expandable.

Choosing a steel-structure warehouse can result in long-term savings and an adaptable space to meet your business needs.

Key Factors Influencing Steel Construction Costs

Several factors can significantly influence the cost to build a steel-structure warehouse. Understanding these can help in better planning and budgeting.

One of the most critical factors is locati0n. Regional differences in labor rates and materials can sway prices considerably. Proximity to suppliers can also affect logistical expenses.

The complexity of the design is another crucial aspect. Custom designs require special engineering, driving up costs. Simple structures generally incur lower steel construction costs.

Here are some of the main factors to consider:

- Location: Influence of regional labor and material prices.

- Design Complexity: Impact of custom features and engineering.

- Market Conditions: Fluctuations in steel prices affecting overall cost.

Market conditions play a pivotal role as well. Steel prices can vary based on global market trends, impacting the total project expense. Being aware of these factors can help you stay within budget and ensure project success.

Steel Structure Pricing: Average Costs per Square Foot

Understanding steel structure pricing is crucial for budget planning. On average, basic steel warehouses cost between $15 to $25 per square foot. This range depends on the simplicity of the design and basic finishings.

For more customized buildings, costs can soar. Custom features might increase pricing to $40 or more per square foot. Features such as advanced HVAC systems and sophisticated designs contribute to these higher costs.

When exploring different pricing tiers, consider the following:

- Basic Structures: $15 – $25 per square foot

- Moderate Customization: Around $30 per square foot

- High-End Customization: $40+ per square foot

by adrian susec (@adrianxsusec)

These figures provide a general idea but remember, final costs will vary. Each project is unique, with varying requirements and specifications. Therefore, obtaining multiple quotes and carefully comparing them is essential before making a decision.

Warehouse Cost Breakdown: Main Components

A comprehensive warehouse cost breakdown involves several main components. Understanding these components helps in effective budgeting and planning. Each component contributes to the overall expense in varying degrees.

Material Costs

Materials account for 50-60% of the total budget. Steel is the primary material, making it a significant part of the cost. Additional materials include insulation, roofing, and siding.

The material costs breakdown generally includes:

- Steel Framework: Structural beams and columns

- Wall and Roof Panels: Metal panels or alternative materials

- Insulation: Essential for energy efficiency

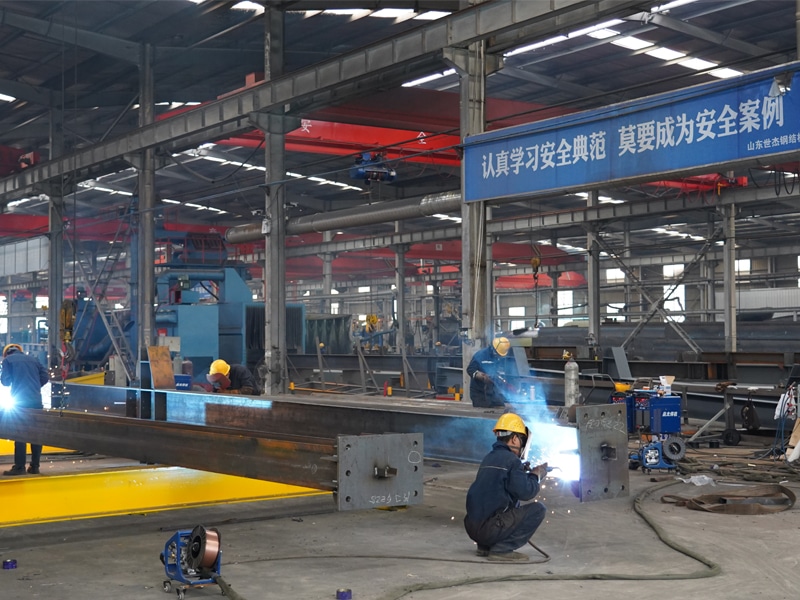

Labor Costs

Labor costs can vary widely. They depend on local wage rates and the complexity of the project. These costs encompass several labor aspects.

Labor costs typically cover:

- Construction Crew: Skilled workers for assembly

- Electrical and Plumbing Work: Installation of utilities

- Finishing Work: Detailing and final touches

Site Preparation and Foundation

Site preparation is crucial for a stable warehouse. It includes land clearing, grading, and laying down a foundation. These tasks require careful planning and execution.

Major site preparation tasks involve:

- Land Clearing: Removing debris and existing structures

- Grading: Leveling the land for proper drainage

- Foundation Work: Constructing slabs or footings

Additional Features and Customizations

Additional features enhance functionality but increase costs. They include customizations tailored to specific needs. Evaluate these extras carefully for cost-effectiveness.

Common additional features include:

- HVAC Systems: Climate control installations

- Technological Integrations: Smart tech for operational efficiency

- Custom Design Elements: Aesthetic or structural uniqueness

by Claudio Schwarz (https://unsplash.com/@purzlbaum)

Understanding these cost components ensures clarity. By analyzing each area, informed budgeting decisions can be made. These decisions guide the project from planning to completion effectively.

How Design and Size Impact Total Warehouse Cost

The design and size of a warehouse significantly influence the total construction cost. A larger warehouse requires more materials and labor, increasing costs. Additionally, complex designs may require special architectural features, impacting the budget further.

Design elements tailored to specific business needs can also raise costs. Features like specialized storage spaces or load-bearing capacity adjustments add complexity. Such modifications often demand additional materials and skilled labor, both contributing to higher expenses.

When planning, consider the following cost-influencing design and size factors:

- Building Footprint: Larger spaces require more resources.

- Design Complexity: Unique architectural features add expense.

- Custom Features: Tailored needs demand additional materials.

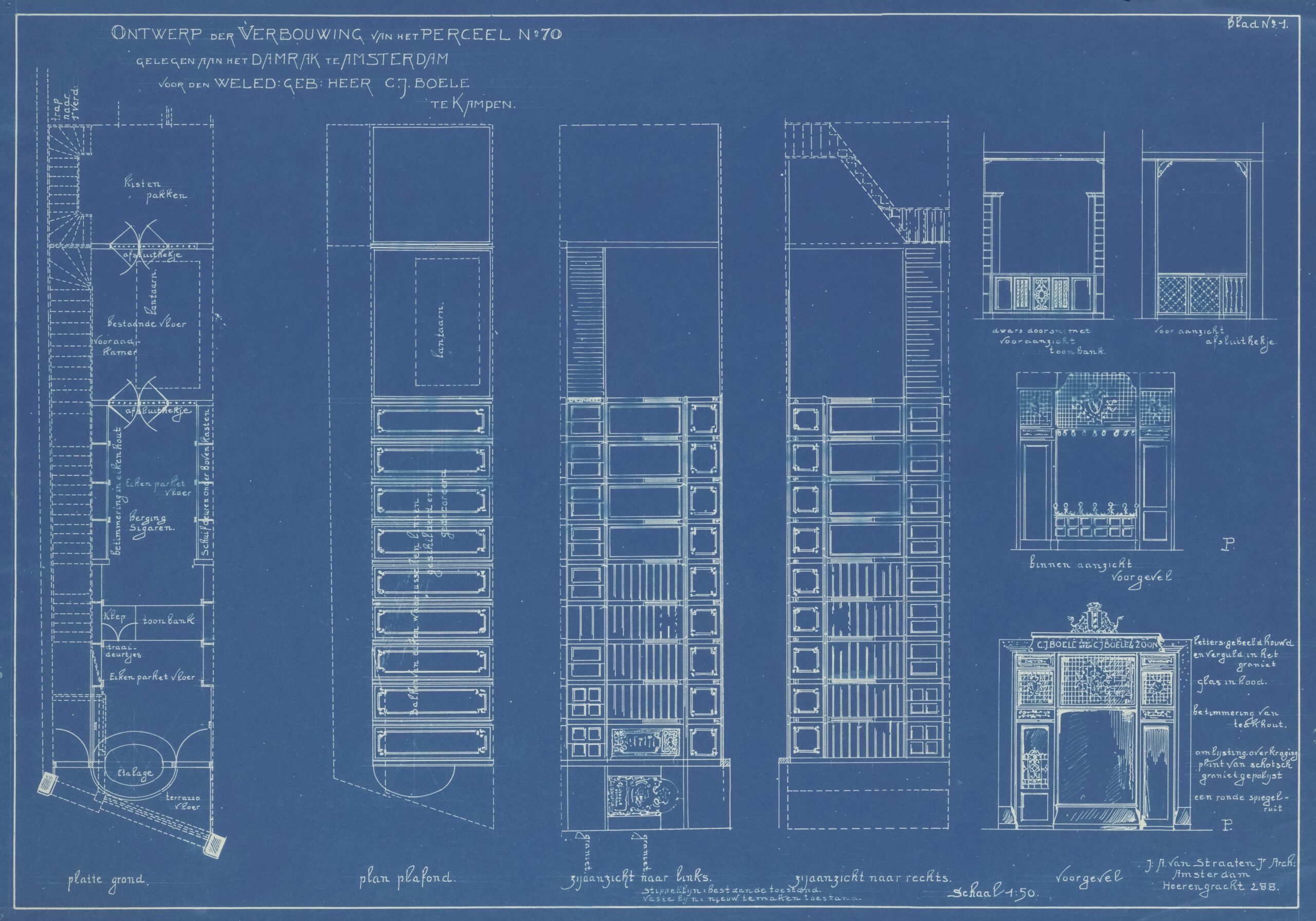

by Amsterdam City Archives (https://unsplash.com/@amsterdamcityarchives)

Balancing design, size, and cost is essential. Assessing needs and resources ensures effective budgeting without compromising functionality.

Regional and Market Factors Affecting Steel Structure Pricing

Regional and market factors play a vital role in determining steel structure pricing. Local availability of materials and labor can significantly alter costs. In regions with limited resources, prices may rise due to higher transportation fees and scarcity.

Market conditions also impact pricing. Fluctuating steel prices due to global demand can affect overall project costs. Staying informed about these trends helps in effective budgeting.

Key factors include:

- Local Material Access: Proximity affects transportation expenses.

- Labor Costs: Regional wages vary by locati0n.

- Steel Market Trends: Global dynamics influence pricing.

by KOBU Agency (https://unsplash.com/@kobuagency)

Understanding and planning for these variables can help mitigate unexpected costs. This ensures that your project remains within budget and schedule.

Cost-Saving Tips for Steel-Structure Warehouse Construction

Building a steel-structure warehouse can be expensive, but cost-saving strategies can help. By planning carefully, you can stay within budget and maximize efficiency. Implementing smart solutions during construction and procurement phases is key.

Consider these tips to control expenses:

- Compare Supplier Quotes: Seek multiple quotes for materials.

- Opt for Pre-engineered Designs: Reduce construction time and costs.

- Implement Energy-efficient Systems: Lower operational expenses long-term.

by Mohamedh Masood (@konmmesmeehaku)

Thinking ahead and making informed decisions can save money and time. Focusing on sustainability and efficiency often reduces costs, adding value to your investment. Planning your project with these tips in mind ensures financial success.

Long-Term Value: Maintenance, Insurance, and Resale

Investing in a steel-structure warehouse offers durable advantages. These buildings often require less maintenance than traditional structures, leading to cost savings. Steel’s resilience also contributes to lower insurance premiums.

Consider the following long-term benefits:

- Reduced Maintenance Costs: Less frequent repairs.

- Lower Insurance: Steel’s strength offers safety benefits.

- High Resale Value: Attracts future buyers with flexibility and durability.

by Max Feilner (@jungrmax)

The long-term value of steel-structure warehouses stems from their adaptability and robustness. These factors enhance their market appeal, ensuring a positive return on your investment.

Frequently Asked Questions About Steel Warehouse Costs

Understanding steel warehouse costs can seem complex. Addressing common questions can offer clarity and facilitate informed decision-making.

Here are answers to frequently asked questions:

- What is the average cost per square foot?

- Do customizations significantly increase costs?

- How do regional factors affect pricing?

In summary, various factors impact costs, including design choices and locati0n. Being well-informed helps in planning a financially sound steel-structure warehouse project.

Conclusion: Planning Your Steel-Structure Warehouse Project

Building a steel-structure warehouse involves careful planning and consideration of multiple factors. By understanding the cost components, such as materials and labor, you can better manage your budget.

It’s essential to factor in market conditions and design preferences. Partnering with experienced professionals ensures optimal outcomes. With the right planning, a steel-structure warehouse can be both cost-effective and a valuable asset for the future.

POURQUOI CHOISIR sdshijie

La construction de structures métalliques sur mesure est notre spécialité.

Plus de projets