Costes de las construcciones metálicas: Una guía completa para presupuestar y planificar

Metal buildings are widely popular in modern industry, commerce, and agriculture due to their durability, rapid construction, and flexible design. However, whether you’re planning to build a warehouse, workshop, agricultural greenhouse, or commercial facility, accurate budgeting and meticulous planning are crucial for project success. This guide will provide a comprehensive understanding of the cost structure, budgeting methods, and planning considerations for metal buildings.

I. Why Choose Metal Buildings?

Before delving into the cost, let’s understand the main advantages of metal construction:

- Durability: Corrosion-resistant, insect-resistant, and fire-resistant.

- Construction Speed: Prefabricated components can shorten construction time by 30-50%.

- Low Maintenance Costs: Compared to traditional buildings, long-term maintenance costs are significantly reduced.

- Flexible Design: Large spans and ample column-free interior spaces.

- Environmentally Friendly and Sustainable: High material recyclability and minimal waste during construction.

II. Detailed Explanation of Metal Construction Costs

The total cost of metal construction typically consists of the following components:

- Design and Engineering Fees (5-10%)

- Architectural Design Scheme

- Structural Engineering Calculations

- Construction Drawings

- Approval and Permit Support

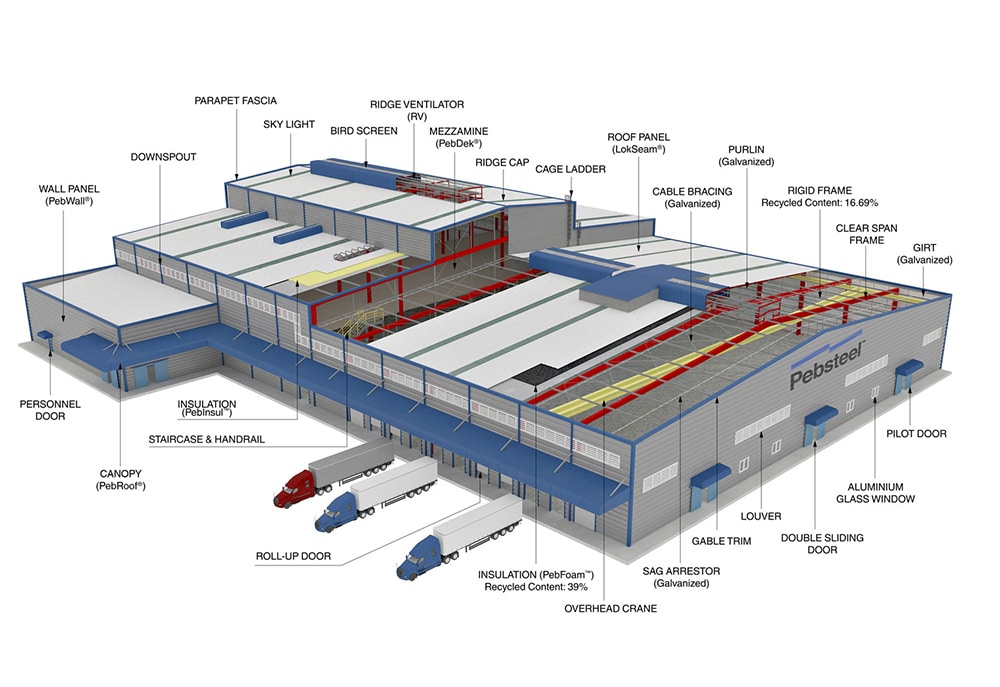

- Material Costs (40-50%)

- Main Structural Materials: Steel beams, columns, purlins

- Enclosure System: Wall panels, roof panels, insulation materials

- Connectors: Bolts, screws, anchors

- Door and Window System: Industrial doors, skylights, access doors

Accessories: Gutters, downpipes, ventilators

- Site Preparation Costs (10-20%)

· Site clearing and leveling

· Foundation and substructure construction

· Utility connections (water, electricity, drainage)

· Temporary facility erection

- Construction and Installation Costs (20-30%)

· Main structure installation

· Enclosure system installation

· Door and window installation

· Interior partition construction

· Subcontracting (electrical, plumbing, etc.)

- Additional Costs and Contingency Budget (10-15%)

· Transportation costs (especially in remote areas)

· Permits and inspection fees

· Unforeseen costs

· Insurance and taxes

III. Key Variables Affecting Costs

- Building Size and Complexity

· Simple rectangular building: Approximately $16-25/square foot

· Building with eaves or multiple floors: Approximately $20-35/square foot

· Special shapes or curved designs: Price may increase by 30-50%

- Material Specifications Selection

- Basic G-60 coated steel vs. high-grade aluminized zinc sheet

- Standard insulation vs. high-performance insulation system

- Ordinary skylights vs. smart dimming materials

- Geographical Location Factors

- Regional labor cost differences

- Transportation distance

- Special design requirements due to local climate (snow load, wind load)

- Foundation conditions (soft soil foundations require additional treatment)

- Functional Requirements

- General warehousing: $18-28/sq ft

- Equipment workshop: $22-35/sq ft

- Cold chain warehouse: $35-50+ sq ft

- Office complex: $40-70+ sq ft

IV. Step-by-Step Budget Planning Guide

Step 1: Define Needs and Objectives

- Determine the main purpose and function of the building

- Estimate the required area (considering future expansion)

- List special requirements (cranes, ventilation systems, etc.)

Step 2: Obtain Preliminary Quotes

- Collect quotes from at least 3-5 suppliers

- Ensure quotes cover the same range (apple-to-apple comparison)

· Note exclusions and additional conditions

Step 3: Detailed Cost Breakdown

Use the following table for a detailed budget:

Project Category | Estimated Cost | Percentage | Remarks

Design & Permits

Site Preparation

Main Materials

Construction & Installation

Internal Systems

Contingency Budget

Total

Step 4: Funding Plan & Timeline

· Phased Payment Schedule (usually payment on progress)

· Coordination of Material Procurement and Construction Timelines

· Consider Seasonal Factors (High Construction Costs in Some Regions During Winter)

V. Practical Cost Reduction Strategies

- Standardized Design: Choosing a supplier’s standard design can reduce costs by 5-15%.

- Advance Planning: Start planning 6-12 months in advance to avoid rush fees.

- Seasonal Procurement: Ordering during off-peak seasons (such as winter) may yield discounts.

- Modular Options: Design in 3-foot increments to reduce material waste.

- Self-Service of Some Work: Such as site clearing, interior finishing, etc.

- Considering Used Materials: Some structural components can utilize high-quality used materials.

VI. Common Pitfalls and Avoidance Methods

- Underestimating Foundation Costs: Professional soil testing can prevent unexpected issues.

- Ignoring Hidden Costs: Clarify whether the quote includes hoisting equipment, temporary facilities, etc.

- Over-Customization: Assess whether customized functions are necessary or can be replaced by standard solutions.

- Ignoring Energy Efficiency: Slightly higher initial investment may lead to significant long-term savings.

- Construction Delays: Clearly define the construction period and liability for delays in the contract.

VII. Long-Term Perspective: Life Cycle Costs

When assessing the cost of metal buildings, their entire life cycle should be considered:

- Maintenance Costs: The average annual maintenance cost of metal buildings is approximately 1/3 that of traditional buildings.

- Energy Efficiency: Good insulation can save 20-40% on energy costs.

- Adaptability: Easy to expand or renovate, adapting to future changes in demand.

- Residual Value: Steel has high recycling value and retains value even after the building’s lifespan.

VIII. Planning Timeline Recommendations

- Preliminary Research (1-3 months): Demand analysis, site selection, preliminary design

- Detailed Design (2-4 months): Construction drawings, engineering calculations, obtaining a quotation

- Permits and Approvals (1-4 months): Submitting applications, handling adjustments

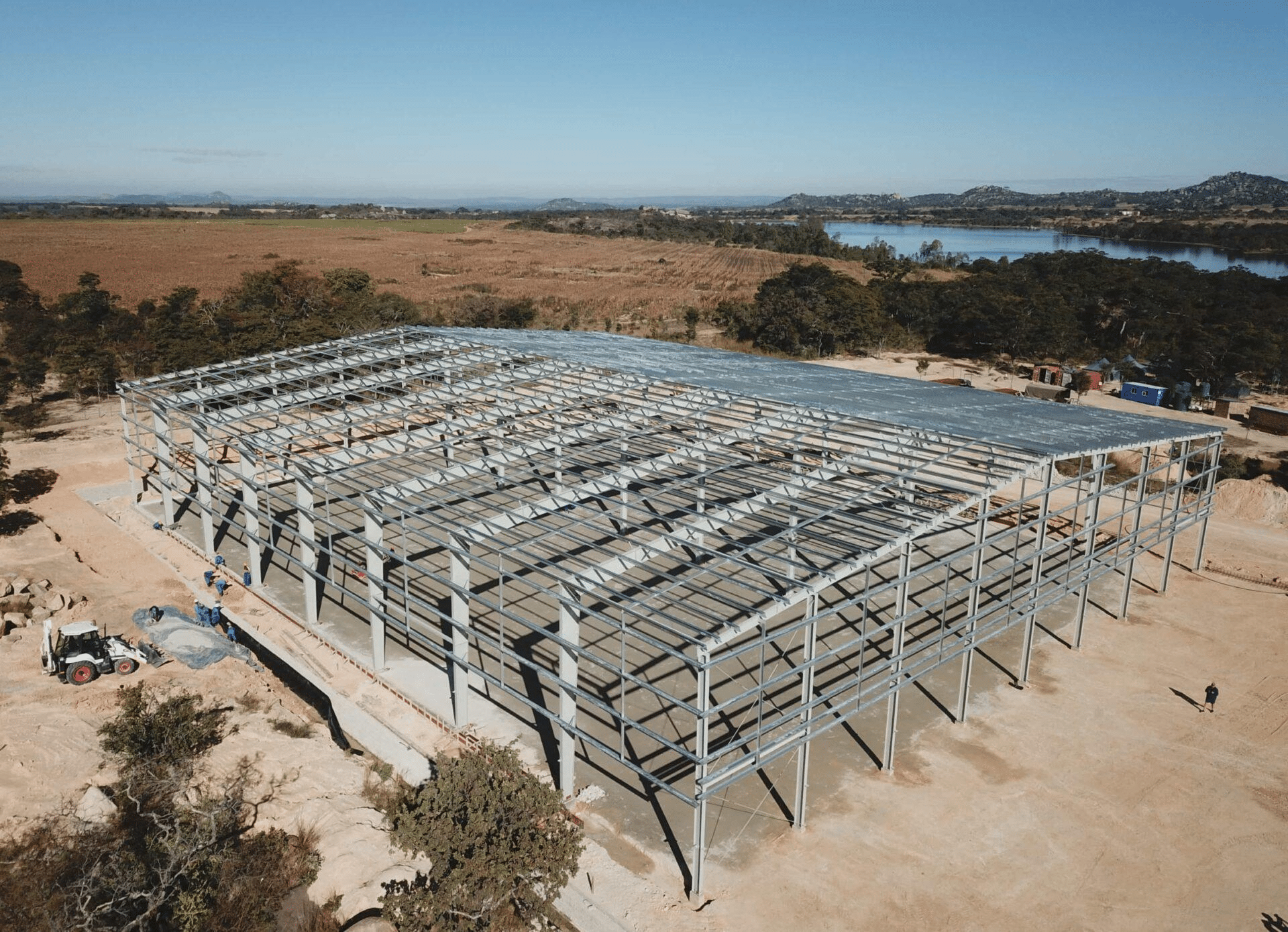

- Procurement and Manufacturing (1-3 months): Material ordering, component prefabrication

- Construction Phase (2-6 months): Foundation, installation, finishing touches

Conclusión

Cost management in metal construction is an art of balance: finding the optimal balance between quality, functionality, and budget. Through detailed planning, transparent supplier communication, and informed decision-making, you can ensure your project is completed on time and within budget, resulting in a high-quality building that meets your long-term needs.

Remember, the cheapest upfront choice is not necessarily the most economical long-term choice. Investing in quality materials, professional design, and good construction will bring you years of reliable service and cost savings. It is recommended to work closely with experienced metal construction contractors and structural engineers; their expertise can help you avoid common mistakes and ensure your investment is worthwhile.

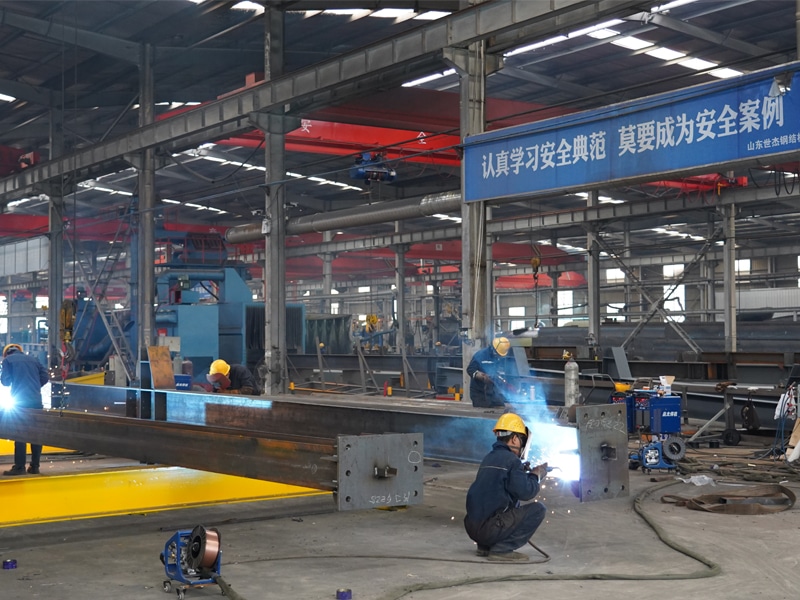

¿POR QUÉ ELEGIR sdshijie?

La construcción de estructuras metálicas a medida es nuestra especialidad.

Más proyectos