Aircraft Hangar Metal Architecture: Robust Guardians of Modern Aviation Infrastructure

In the aviation industry, whether it’s a busy international airport, a regional aviation hub, a private flying club, or a military base, aircraft hangars are indispensable core facilities. They are not only places for parking, maintaining, and repairing aircraft, but also robust barriers protecting these high-value assets from sun, rain, wind, frost, snow, and hail. Among the many forms of hangar architecture, metal architecture, with its superior performance and flexibility, has become the globally recognized mainstream choice.

I. What is an Aircraft Hangar Metal Architecture?

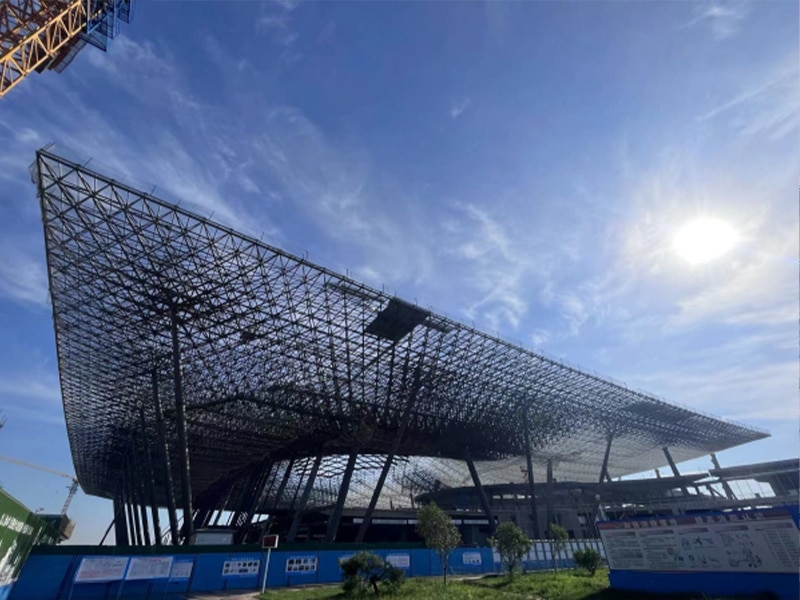

An aircraft hangar metal architecture primarily refers to industrial buildings with ultra-large spans and large spaces, constructed using high-strength steel (such as hot-dip galvanized steel) as the main structural frame, combined with metal wall and roof systems (usually color-coated steel sheets or sandwich panels). Its core lies in utilizing the strength and plasticity of metal materials, through precise design and construction, to achieve a spacious environment without intermediate columns, meeting the needs of accommodating aircraft and their maintenance equipment.

II. Core Advantages of Metal Hangars

- Unparalleled Strength and Span Capacity

· The high strength-to-weight ratio of steel makes it possible to construct ultra-large spans (typically 60 meters, 100 meters, or even larger). This provides unobstructed interior space for large wide-body passenger aircraft, military transport aircraft, or multiple small aircraft simultaneously, greatly improving space utilization and operational efficiency.

- Superior Durability and Low Maintenance Costs

· Modern steel structures undergo anti-corrosion treatments (such as galvanizing), and the metal plate surfaces are covered with weather-resistant coatings, effectively resisting moisture, salt spray, UV corrosion, and extreme weather. This gives metal hangars a service life of decades and simplifies routine maintenance, eliminating the need for frequent painting or repairs like traditional buildings.

- Fast Construction and Flexible Construction

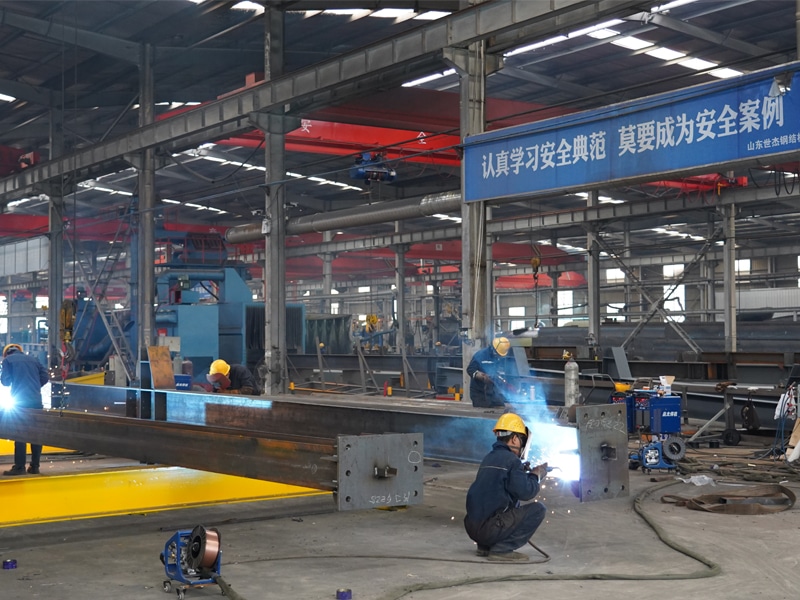

· Major components are prefabricated in the factory, ensuring high precision and stable quality. On-site assembly is done in a modular fashion, like “building blocks,” significantly shortening the construction cycle (30%-50% shorter than traditional buildings) and allowing for faster commissioning. This flexibility also facilitates future expansion or relocation. 4. Economical and Efficient, Low Overall Cost

While initial material costs may be high, the overall cost over its entire lifecycle is significantly advantageous due to short construction periods, reduced labor costs, and extremely low maintenance expenses. The metal structure itself can also serve as the framework for various systems (such as lighting, fire protection, and ventilation), offering high integration.

- Flexible Design, Customizable Functions

Metal buildings can easily accommodate various door designs, such as sliding doors, folding doors, side-sliding doors, or hydraulic lift doors, to accommodate aircraft of different sizes and types. Internal layouts (such as office areas, maintenance areas, parts storage, and paint booths) can be freely divided according to the owner’s needs. The exterior can also be modernized through different panels and colors.

- Compliant with Sustainable Development Concepts

Steel is a 100% recyclable green material. Dry construction reduces construction waste. Furthermore, metal roofs can easily integrate solar photovoltaic systems, providing green energy for hangar operations.

III. Common Types and Application Scenarios

- General Aviation Hangars: Used for parking small private jets, business jets, and helicopters. Typically of moderate span, emphasizing economy and practicality.

- Commercial Aviation Maintenance Hangars: Used for scheduled maintenance and overhauls of large passenger aircraft. Large span, complex structure, equipped with overhead cranes, work platforms, and ground support equipment interfaces, and must meet stringent fire safety and environmental protection requirements.

- Military Aircraft Hangars: In addition to meeting parking and maintenance needs, they have higher requirements for the structure’s explosion resistance and protective performance, requiring a more robust and concealed design.

- Rapid Deployment/Temporary Hangars: Utilizing lightweight steel structures and membrane or sheet materials, they can be quickly erected and are commonly used for temporary deployments, disaster relief, or military front lines.

IV. Key Design Considerations

Building a fully functional metal hangar is far more than simply “building a shed.” The following factors must be comprehensively considered:

- Precise Requirements Analysis: The type, number, and dimensions (wingspan, height, length) of the aircraft to be parked, as well as the required maintenance level and equipment list.

- Door System Selection: The main door is the “throat” of the hangar. The most suitable door type and its opening/closing mechanism must be selected based on aircraft size, usage frequency, site conditions, and budget.

- Structural Safety and Compliance: The design must comply with local building codes, load standards (wind load, snow load, seismic load), and special safety regulations in the aviation industry.

- Integrated Supporting Facilities: This includes lighting systems (high-brightness shadowless lighting is required), ventilation and heating systems, fire protection systems (such as early smoke detection and foam extinguishing), electrical and drainage systems, etc.

- Foundation and Ground Treatment: A solid foundation is the basis of safety. The ground typically requires high-strength concrete and may undergo chemical protection treatment to cope with oil contamination.

Conclusión

Aircraft hangar metal structures represent a perfect combination of modern industrial building technology and aviation operational needs. It is not merely a physical space of reinforced concrete, but a strategic infrastructure that ensures flight safety, improves operational efficiency, and protects substantial assets. With continuous advancements in materials science and construction technology, future metal hangars will evolve towards greater intelligence, greener design, and more integrated functions, continuing to provide the most reliable land-based support for human aviation.

¿POR QUÉ ELEGIR sdshijie?

La construcción de estructuras metálicas a medida es nuestra especialidad.

Más proyectos