Factores clave que influyen en el coste de los almacenes de estructura metálica

Construction Cost of Steel Structure Warehouses

Understand the Cost Details of Steel Structure Warehouses Steel structure warehouses have become the first choice for logistics and industrial production due to their efficient construction, high space utilization and strong durability. They are widely adopted in e-commerce logistics, manufacturing parts storage, and bulk cargo warehousing. However, the cost varies significantly across projects, ranging from several hundred to over a thousand yuan per square meter—even for warehouses of similar sizes—due to differences in materials, design, and construction conditions. In fact, the cost of steel structure warehouses is constrained by multiple interrelated factors; mastering these key variables is essential to precise cost control and maximizing cost-effectiveness for your project.

Steel structure warehouses

Material Cost of Steel Structure Warehouses Steel cost is the core pillar, accounting for 35%-45% of the total cost. The unit price of mainstream Q235B steel is about 4,500-5,200 yuan per ton, while high-strength Q355B is 800-1,300 yuan more expensive per ton due to better load-bearing capacity and corrosion resistance—ideal for large-span or heavy-load warehouses.

Steel prices fluctuate sharply under the influence of international energy prices, domestic production policies, and market supply-demand; during peak seasons, the price per ton rises by over 10%, which may increase the cost of a 3,000㎡ warehouse by tens of thousands of yuan. For example, a 3,000㎡ warehouse typically consumes 200-300 tons of steel, so a 500-yuan per ton price hike adds 100,000-150,000 yuan to the total cost. In addition, although steel from large mills is 50-150 yuan per ton more expensive, its stable quality and precise dimensions reduce subsequent rework costs and ensure structural safety.

Roof and Wall System Design and specifications directly affect steel consumption and overall costs. The 9-12m span offers the highest cost-performance, as it balances material use and space efficiency; spans exceeding 25m require heavy-duty steel beams and columns, increasing costs by 15%-20% due to additional material and processing needs. For every 1m increase in eave height, the cost of walls and roofs rises by 8%-10%, as it requires more cladding materials and supporting steel structures.

Meanwhile, economies of scale are significant: warehouses over 5,000㎡ have 20%-30% lower unit costs than small ones through bulk purchasing of steel and streamlined construction processes. Reasonable column spacing design (usually 6-8m) can also balance cost and space utilization—overly large column spacing will unnecessarily increase steel usage, while overly small spacing wastes space.

There are large differences in enclosure system configurations, which directly impact both cost and performance. Ordinary 50mm EPS sandwich panels cost 80-100 yuan/㎡, suitable for general storage in temperate regions; fireproof and thermal insulation rock wool sandwich panels cost 120-150 yuan/㎡, and the cost will increase by another 20%-30%

with increased thickness (e.g., 75mm or 100mm panels for cold storage). Standing seam metal roofing is 30% more expensive than roll roofing but has a service life of over 20 years and better waterproof performance, making it more cost-effective in the long run. The quality of auxiliary materials such as doors, windows, sealants, and gutters also cumulatively affects the total cost—high-quality aluminum alloy doors and windows, for instance, are 50%-80% more expensive than ordinary steel ones but offer better airtightness and longer service life, reducing maintenance costs.

Steel Structure Workshop Wall Panel Maintenance System

Labor and Construction Costs Construction and regions hide hidden costs that are often overlooked. Labor costs in first-tier eastern cities are 280-350 yuan per workday, 30%-50% higher than in central and western regions, and will increase by another 10%-15% for construction in winter and rainy seasons due to reduced work efficiency. Transportation costs also vary greatly:

proximity to steel mills saves 5%-10% on transportation, as long-distance rail or road transport adds 30-80 yuan per ton. Remote areas with poor road conditions have a transportation premium of over 15% due to increased delivery difficulty. Mountainous areas and sites with high groundwater levels require piling foundations, whose cost is 20%-30% higher than ordinary strip foundations—this is because such sites need more materials and longer construction time to ensure foundation stability.

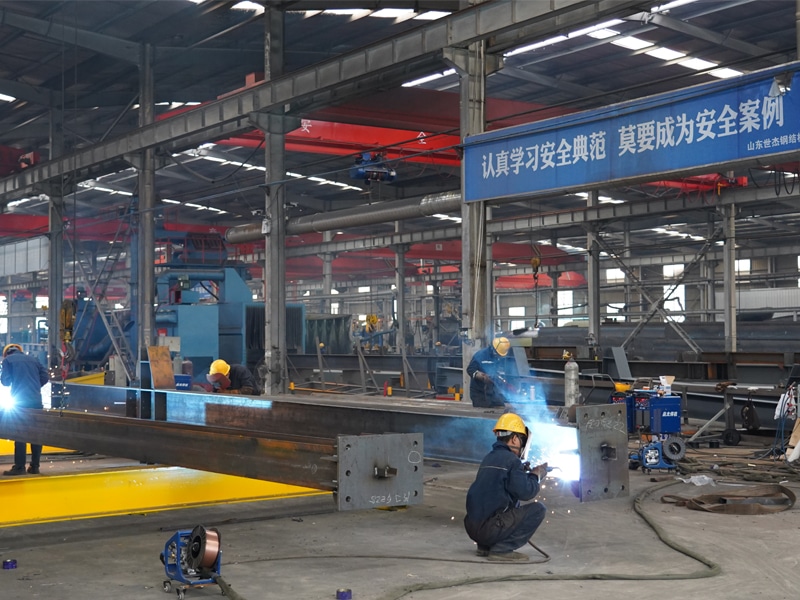

Manufacturing and Processing Costs Customization needs drive up costs significantly, as they require non-standard design and processing. For warehouses equipped with crane beams for heavy cargo handling, the processing fee per ton of components increases by 200-400 yuan, and the cost is even higher when the crane tonnage exceeds 20 tons (needing thicker steel plates).

Chemical and coastal areas require heavy anti-corrosion coatings, which are 500-800 yuan per ton more expensive than ordinary paint but have a service life of 15-20 years—far longer than the 5-8 years of ordinary coatings. Adding functional systems such as thermal insulation, ventilation, or intelligent fire protection will increase the cost by another 80-150 yuan per square meter; intelligent systems like temperature and humidity monitoring can add an extra 30-50 yuan per square meter but improve operational efficiency.

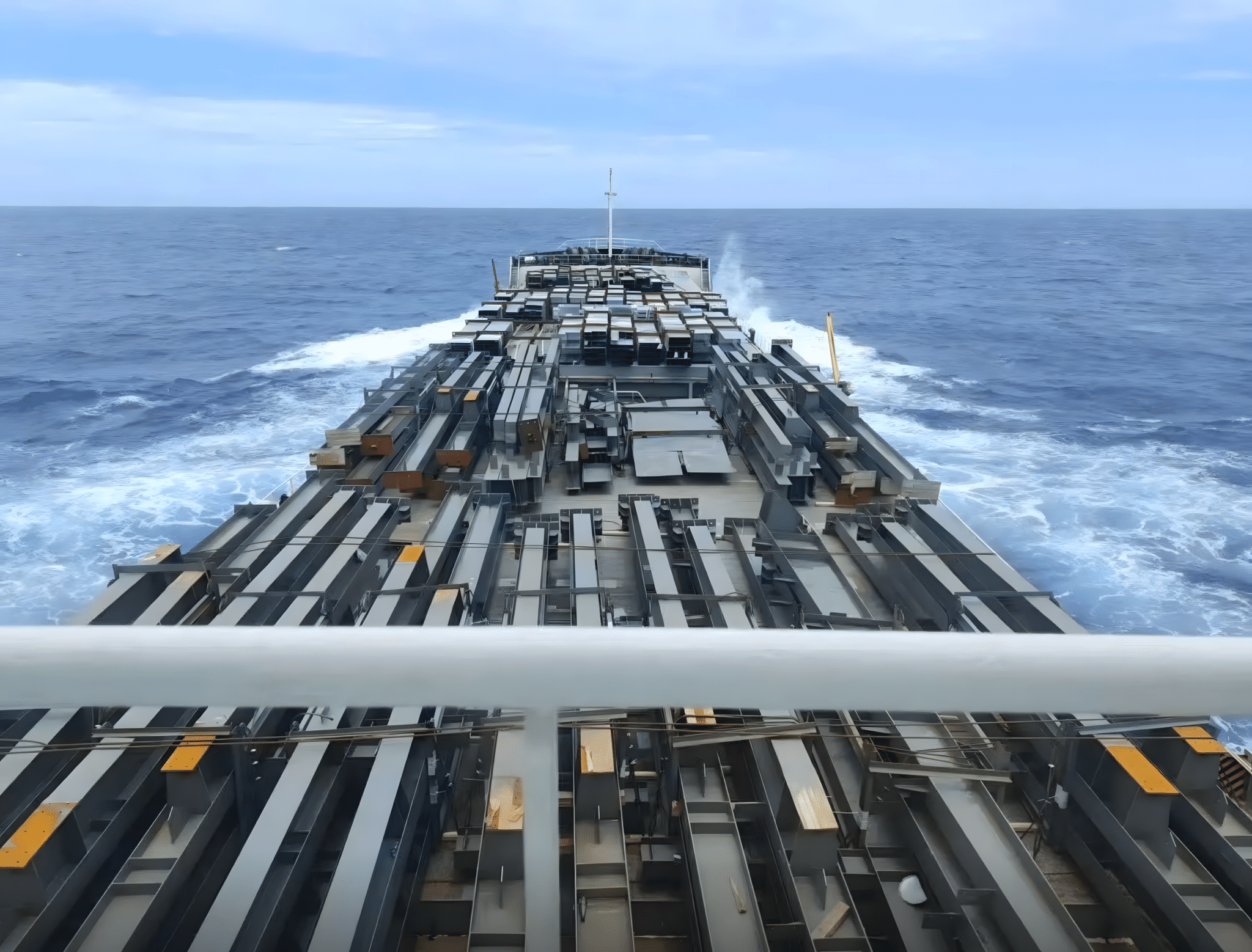

Transportation and Logistics Costs Steel structure warehouses are usually prefabricated in the factory and then transported to the construction site. The transportation cost depends on: 1.The distance between the factory and the construction site

2.The dimensions and weight of steel components

3.Packaging and loading requirements

4.Local transportation regulations

Oversized steel components may require special transportation permits or escort vehicles, thereby increasing logistics costs. Transportation expenses can be effectively reduced through modular design and optimized component dimensions.

¿POR QUÉ ELEGIR sdshijie?

La construcción de estructuras metálicas a medida es nuestra especialidad.

Más proyectos