A Comprehensive Cost Analysis of Steel Structure Buildings: A Buyer’s Guide to Evaluation

When considering building a Stahlkonstruktion building, the most crucial question is undoubtedly, “How much will this actually cost?” However, the real answer is far more complex than a simple number. This article aims to provide you with a clear and transparent cost structure framework, helping you understand all the key factors influencing your final investment and enabling you to make informed decisions.

Understanding Costs: Why There’s No “Standard Price”?

The first core understanding that must be established is that there is no “standard price list” for steel structure buildings that applies to all projects. Every building is unique, and its final cost is the result of the dynamic interaction of multiple variables. Trying to find a ready-made unit price from the internet or others’ experiences often leads to significant budget deviations or mismatches in project specifications.

Total cost is primarily determined by the following dimensions:

· Building Function and Design: Is it a simple warehouse for storing goods, or a food processing plant requiring precise temperature control? Is it a train station with a large-span, column-free space, or a multi-story creative office loft? Function determines the complexity of the design.

· Scale and Dimensions: Building area, span, eaves height, presence of mezzanine, etc.

- Geographical Location: Labor costs, material transportation distances, geological conditions (directly affecting foundation costs), and local regulations vary across regions.

- Material and Process Standards: Steel quality and strength, anti-corrosion coating grade, cladding thickness and core material, door and window configuration, etc.

- Market Environment: Price fluctuations of commodities (such as steel), supply and demand changes during peak and off-peak seasons.

Core Cost Module Breakdown: Where is your investment going?

To control your budget, you must understand the components of the total cost. Below is a complete cost breakdown of steel structure construction from scratch:

- Design and Preliminary Preparation

This is the blueprint stage of the project. Although the cost percentage is not high, it determines the efficiency and rationality of all subsequent investments.

- Design Fees: Includes structural design, architectural design, and construction drawings. Complex projects or those requiring approvals incur higher costs.

- Geological Survey Fees: Obtaining reliable soil data is fundamental to a safe and economical foundation design.

- Approval and Permit Fees: Various administrative fees that may arise according to local regulations.

- Foundation and Substructure Engineering

This is the part that anchors the blueprints to the ground. Its cost is greatly affected by geological conditions and is the most variable part of the budget.

- Earthwork: Excavation, backfilling, and leveling.

- Concrete Foundation: Including the reinforcement, formwork, pouring, and curing of foundation caps and ground beams.

- Embedded Components: Precisely embedded anchor bolts and other connecting components.

Key Note: Excessive cost-cutting in foundation engineering may lead to building settlement or cracking, resulting in extremely high rework costs.

- Main Steel Structure

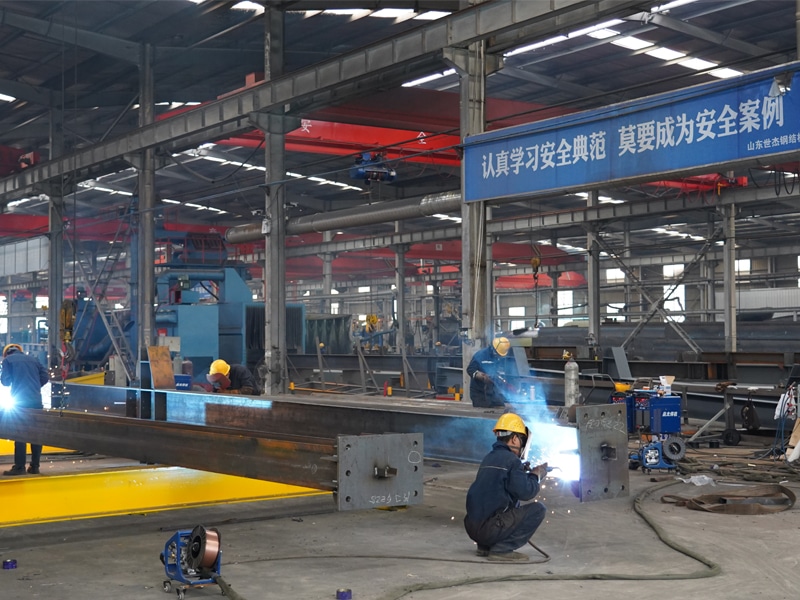

This is the skeleton of the building and the core embodiment of the “steel structure.”

- Supply and Processing of Main Steel Components: Includes major load-bearing components such as steel columns, steel beams, and trusses. Cost depends on the amount of steel used, cross-sectional dimensions, processing complexity, and surface treatment standards (such as sandblasting, primer, and topcoat).

- Secondary Structural System: Includes purlins, wall beams, and bracing, ensuring the stability of the main structure and supporting the enclosure system.

- Installation and Lifting: On-site installation costs by a professional team, including machinery (such as crane) usage fees.

- Enclosure System

This is the building’s “skin,” determining its sound insulation, heat insulation, fire resistance, waterproofing, and appearance.

- Roofing System: Options include single-layer profiled steel sheets (with insulation) or more integrated sandwich panels (core materials such as rock wool and polyurethane, with varying fire resistance and insulation properties).

- Wall System: Also offers a variety of panel options and includes designs for openings such as doors, windows, skylights, and ventilation louvers.

- Edge Finishing and Waterproofing: Gutters, downpipes, and edge flashing at joints; details determine the building’s durability.

- Auxiliary and Functional Systems

This part provides the building with its actual functional uses and often varies greatly depending on specific needs.

- Electrical System: Lighting, power distribution, lightning protection and grounding.

- Water Supply and Drainage System: Indoor and outdoor drainage, sanitary water supply.

- Fire Protection System: Fire hydrants, sprinklers, and alarm devices according to the building’s hazard level requirements.

- Process Equipment Supporting Facilities: Such as crane brackets and tracks, ventilation and dust removal ducts, equipment platforms, etc.

- Interior Decoration: Partitioning and decoration of offices, restrooms, and other areas.

Buyer’s Roadmap: How to Obtain and Evaluate Solutions

Understanding the cost structure allows you to start the project professionally:

- Define and document your needs: Create a requirements specification that clearly defines the building’s purpose, dimensions, internal space requirements (e.g., headroom, presence or absence of columns), equipment load, fire and insulation ratings, appearance requirements, and future expansion possibilities.

- Seek professional design and preliminary solutions: Prioritize suppliers who can provide integrated design services. A professional design solution based on your needs is the foundation for accurate price comparison, ensuring all quotes are competitive on an equal footing.

- Obtain a structured, transparent quotation: Supplier quotations must be broken down according to the aforementioned cost modules. When comparing, focus on:

- Material specifications: Steel grade, coating, plate thickness, core material density, and fire resistance rating.

- Scope of services: Does the quotation include design, transportation, installation, permitting assistance, and after-sales service?

- Construction standards: Welding processes, corrosion protection processes, and installation precision standards.

- Establish a “Total Cost of Ownership” perspective: The option with the lowest initial investment may have a higher total cost due to higher maintenance costs, higher energy consumption, or shorter lifespan. Evaluation should comprehensively consider the building’s durability, operating energy consumption, and maintenance requirements.

Conclusion: Invest in value, not just tonnage.

Building a Stahlkonstruktion building is essentially an investment in a spatial solution that meets your long-term functional needs. The wisest expenditure is not about pursuing the lowest initial price, but about obtaining a safe, durable, efficient, and reasonably priced high-quality asset through professional design, appropriate material selection, and reliable construction.

Once you grasp the logic behind cost breakdown, you transform from a passive inquirer into a savvy buyer capable of effectively communicating with professionals and collaboratively optimizing solutions. This understanding forms the most solid foundation for your project’s success.

WARUM SDHJIE WÄHLEN?

Der Bau maßgeschneiderter Metallkonstruktionen ist unsere Spezialität.

Weitere Projekte