Vergleichende Analyse von Stahlfertigteilen und kaltgeformten Stahlkonstruktionen

In the world of architecture, choosing a structural system is like choosing a skeleton for a building—it determines the building’s form, capacity, and lifespan. Many project decision-makers face a dilemma when confronted with precast steel structures and cold-formed thin-walled steel structures (light steel structures). This article will offer a new decision-making framework from the perspective of project genes.

Re-understanding the Two Systems: More Than Just a Difference in Steel

Precast Steel Structures: The “Heavy Skeleton” of Buildings

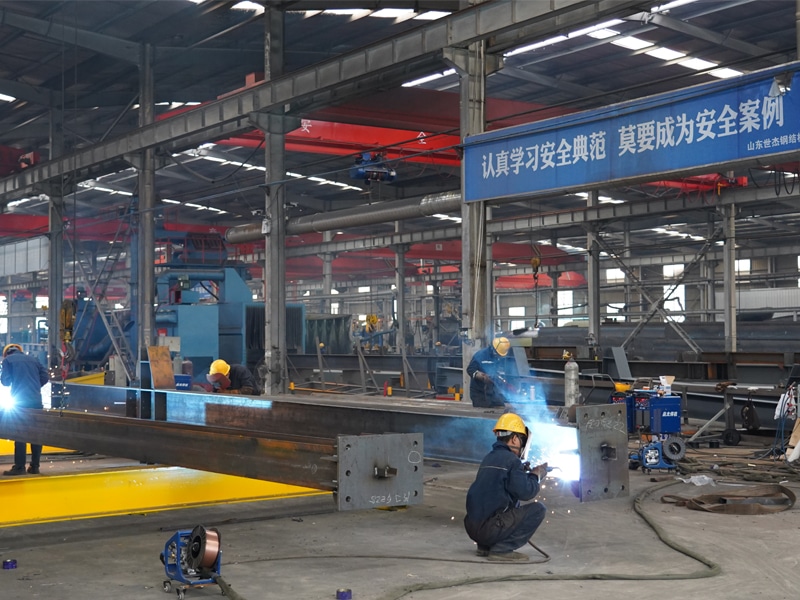

Precast steel structures are heavy-duty steel structure systems formed through hot rolling processes. These steels are shaped into H-shaped, I-shaped, or box-shaped sections at high temperatures, acting as the “main skeleton” of the building, bearing the heavy responsibility of overall load transfer.

Cold-Formed Thin-Walled Steel Structures: The “Precision Ribs” of Buildings

Cold-formed thin-walled steel is a lightweight structural system formed by precision rolling thin steel plates (typically 0.5-3mm) at room temperature. It is more like a “precision rib network” of buildings, forming a stable system through a large number of standardized components.

New Dimensions of Decision-Making: Beyond Traditional Comparisons

Dimension 1: Project “Lifecycle Energy Distribution”

Energy Distribution of Precast Steel Structure Projects:

· Design and Manufacturing Phase: High Energy Input (Detailed Design, Heavy Manufacturing)

· Transportation Phase: Medium Energy Input (Transportation of Large Components)

· On-Site Installation: Relatively Efficient (Rapid Lifting of Large Components)

· Operation Phase: Low Maintenance Energy Input (High Durability)

· Dismantling and Recycling: High-Value Recycling (Steel is Fully Recyclable)

Energy Distribution of Cold-Formed Thin-Walled Steel Structures:

· Design and Manufacturing Phase: Medium Energy Input (Standardized Design, Precision Manufacturing)

· Transportation Phase: Low Energy Input (Compact Packaging, Lightweight Transportation)

· On-Site Installation: Extremely Efficient (Manual Handling, Rapid Assembly)

· Operation Phase: Medium Maintenance Input (May Require More Maintenance)

· Dismantling and Recycling: High-Efficiency Recycling (Materials are 100% Recyclable)

Dimension 2: Project “Uncertainty Tolerance”

High Uncertainty Projects (Demands May Change, Functions May Be Adjusted):

· Significant Advantages of Precast Steel Structures: Large Spaces and Fewer Column Grids Provide Flexibility for Future Retrofitting

· Cold-formed thin-walled structures have many limitations: numerous load-bearing walls and partitions, restricting spatial reconfiguration.

For projects with low uncertainty (clear functions, stable demand):

- Cold-formed thin-walled structures perform exceptionally well: precisely matching needs and avoiding “over-design.”

- Precast steel structures may have “excessive capacity”: paying extra costs for unnecessary potential.

Dimension Three: The Project’s “Time Value Curve”

For projects with high time value (early completion, early benefits):

- Cold-formed thin-walled structures offer significant advantages: off-site prefabrication can reach 85%, and on-site construction speed is 30-50% faster than traditional methods.

- Precast steel structures also have acceleration options: modular prefabrication, but costs increase accordingly.

For projects with moderate time value:

- Precast steel structures can proceed at a traditional pace, optimizing the balance between cost and quality.

Hidden Costs: Easily Overlooked Factors

Technical Coordination Costs

Precast steel structures often require coordination with large equipment and complex pipeline systems, resulting in high design coordination costs.

Cold-formed thin-walled structures, on the other hand, are highly integrated with building interior systems, offering lower interior coordination costs but requiring a dedicated design team. Climate Adaptability Costs

In high-temperature, high-humidity, or corrosive environments:

· Precast steel structures: require thicker coatings or higher-grade steel

· Cold-formed thin-walled structures: require more stringent sealing and moisture-proofing measures

Expansion and Retrofit Costs

When expansion is needed in 10 years:

· Precast steel structures: relatively easy to connect to new structures

· Cold-formed thin-walled structures: may require independent expansion or complex connections

Emerging Trends: The Modern Evolution of Two Systems

The “Lightweight Revolution” of Precast Steel Structures

Modern precast steel is no longer the traditional symbol of “bulky.” Through the application of high-strength steel and optimized design, modern precast steel structures can be 20-30% lighter than traditional solutions, encroaching on the territory originally belonging to light steel structures.

The “High-Rise Breakthrough” of Cold-Formed Thin-Walled Structures

Through innovative connection technologies and hybrid designs, cold-formed thin-walled structures have been successfully applied to 8-10 story mid-rise buildings, breaking the original height restrictions.

Differences in Digital Empowerment

Both systems benefit from BIM technology, but in different ways:

· Precast steel structures: BIM is primarily used to coordinate large components and complex systems.

· Cold-formed thin-walled structures: BIM directly drives manufacturing, achieving “design as production”.

Decision Matrix: Profiling Your Project

Assess your project in the following six aspects (1-5 points each):

- Spatial freedom requirements (Do you need large spaces and few columns?)

- Schedule sensitivity (What is the value of completing ahead of schedule?)

- Budget sensitivity (How stringent is the initial budget?)

- Future uncertainty (Will the functionality change?)

- Sustainability weight (How important are environmental requirements?)

- Local technical capabilities (What types of skilled teams are available locally?)

Scoring bias towards precast steel structures if: Spatial freedom (4-5 points), future uncertainty (4-5 points), local technical capabilities (advantages in precast steel)

Scoring bias towards cold-formed thin-walled structures if: Schedule sensitivity (4-5 points), budget sensitivity (4-5 points), sustainability weight (4-5 points)

Innovation path: A third option

Modern projects don’t have to be either one or the other. Hybrid structural systems are becoming the optimal solution for many projects:

“Precast Steel Frame + Cold-Formed Thin-Wall Infill” Model

- Precast steel main frame provides ample space and primary load-bearing capacity.

- Cold-formed thin-wall infill for internal partitions and secondary structures improves precision and speed.

“Phase-Based Hybrid” Strategy

- Rapidly constructed cold-formed thin-wall infill structures meet urgent needs in Phase I.

- Precast steel structures are used for expansion and upgrades in Phase II.

“Performance-Oriented Hybrid” Solution

- Precast steel is used for primary load-bearing systems such as seismic and wind resistance.

- Cold-formed thin-wall infill for non-structural and interior components.

Your Project, Your Choice

There is no absolute right or wrong choice when selecting a structural system, only the most suitable one. We recommend making decisions based on the following steps:

- Define your core value: What is the most non-negotiable aspect of your project?

- Draw a complete cost curve: including design, construction, operation, modification, and demolition.

- Assess the local ecosystem: Which system has a more mature supply chain in your region?

- Consider future possibilities: How much flexibility should be reserved for unforeseen changes? 5. Visualizing the Result: Imagine the building’s possible state in 10 and 20 years.

The choice of building structure ultimately boils down to a choice of values: leaning towards enduring solidity or agile adaptation? Investing in present perfection or preserving future possibilities?

In the context of sustainable development, both systems are constantly evolving, and the gap is narrowing. True wisdom may not lie in choosing the “better” system, but in how to make the chosen system better serve your project.

Remember: the best structural system is not the strongest or the cheapest, but the one that grows and breathes with your project.

WARUM SDHJIE WÄHLEN?

Der Bau maßgeschneiderter Metallkonstruktionen ist unsere Spezialität.

Weitere Projekte