Key Preparations Before Starting a Metal Construction Project

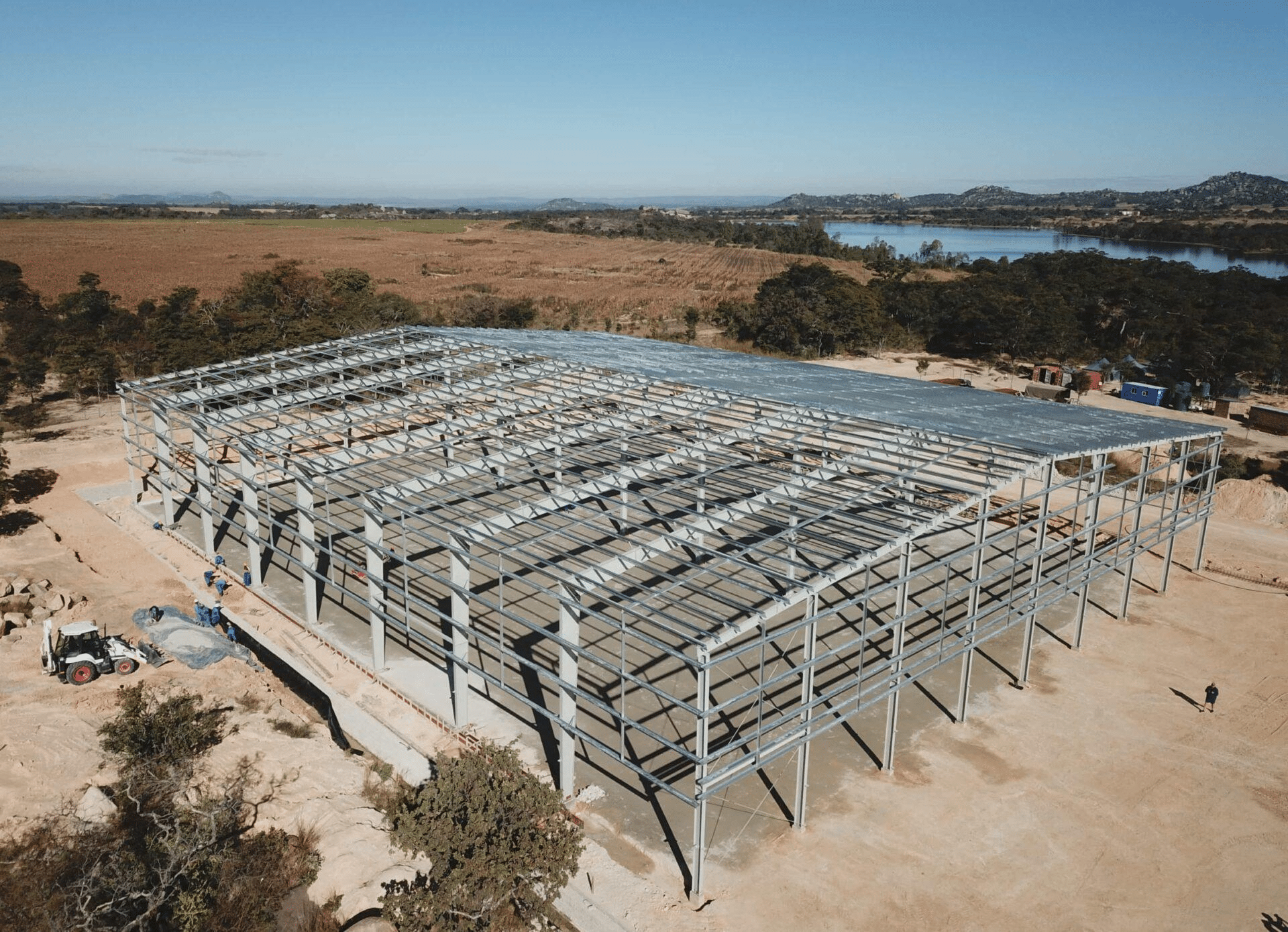

Metal construction projects, with their advantages of high strength, fast construction, flexible design, and economic durability, are widely used in industrial plants, warehousing facilities, stadiums, commercial buildings, and other fields. However, to ensure project success, thorough pre-construction preparation is crucial. Before starting construction, be sure to understand the following key points.

I. Clarify Project Needs and Objectives

- Functional Positioning and Purpose

· Building Purpose: Clarify whether the building will be used for production, warehousing, office, or a multi-functional combination. Different uses have vastly different requirements for space, load, and environment.

· Future Expandability: Are future expansions or functional conversions considered? Interfaces or spaces should be reserved in the design.

- Budget and Timeframe

· Overall Budget: Includes all costs such as design, materials, construction, and approvals. It is recommended to reserve 10%-15% as contingency funds.

- Construction Period Requirements: While metal buildings can be constructed relatively quickly, a well-planned entire lifecycle from design to acceptance is crucial to avoid compressing the schedule and compromising quality.

II. Metal Materials and Design Selection

- Structural Material Types

- Steel Types: Understand the performance differences between common steels such as Q235 and Q345, and select based on load, span, and corrosive environment.

- Coatings and Corrosion Protection: Hot-dip galvanizing and spraying can significantly extend the building’s lifespan, especially in humid, coastal, or industrially polluted areas.

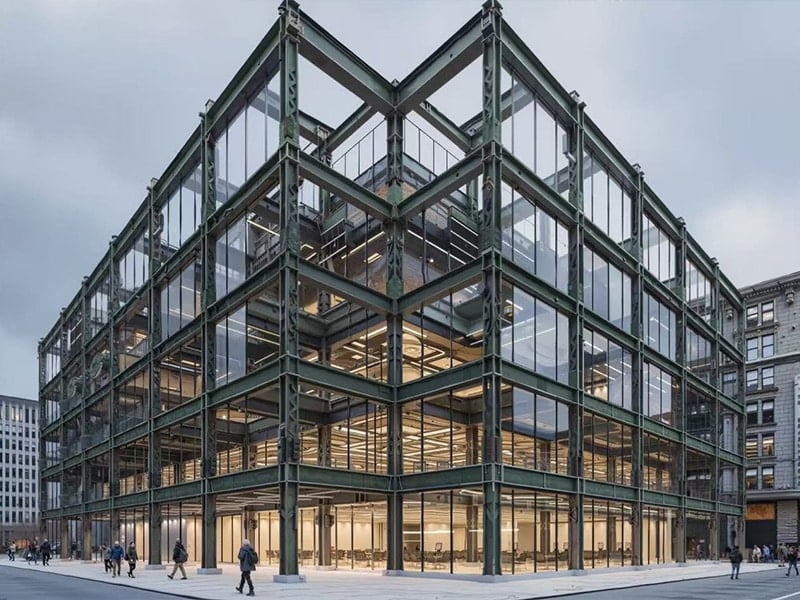

- Design Style and Flexibility

- Traditional vs. Modern Design: Metal buildings are not limited to rectangular factory buildings; aesthetically pleasing modern designs can be achieved through curves and facade decorations.

- Prefabrication Level: Prefabricated components can improve construction speed and quality, but design accuracy must be ensured, and changeover costs are higher.

III. Selection and Collaboration of Professional Teams

- Choosing Experienced Partners

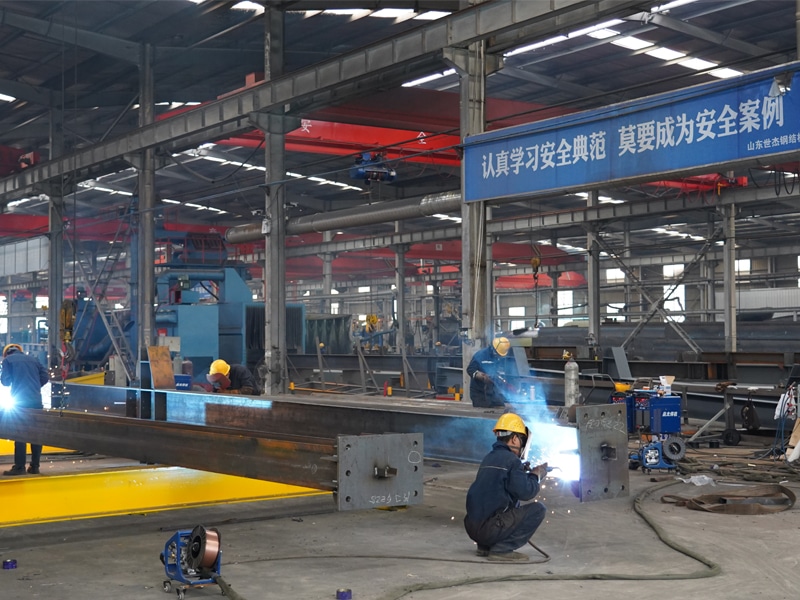

- Design Firm: Find a design institute with specialized qualifications in metal structures to ensure a balance between structural safety and economic efficiency. * Construction Team: Examine the contractor’s past metalwork projects, paying particular attention to their specialized technical skills in welding, hoisting, etc.

- Clearly Define Responsibilities:

- **Sign a detailed contract, clearly defining the responsibilities of the design, supply, and construction parties to avoid disputes arising from ambiguity.

IV. Laws, Approvals, and Standards Compliance:

- 1. Local Approval Requirements:

- Land Use and Planning Permit: Ensure the project complies with land use and urban master planning.

- Building Approval: Submit structural calculations, construction drawings, and other materials for review by the local housing and construction department.

- Compliance with Industry Standards:

- National Standards: Follow the Code for Design of Steel Structures (GB 50017) and the Technical Code for Cold-Formed Thin-Walled Steel Structures (GB 50018).

- Safety and Environmental Protection: Construction must comply with regulations regarding safe production, noise control, and waste management.

V. Construction and Risk Management:

- **1. *Site Condition Assessment:*

- Geological Survey: Conduct a formal geotechnical engineering survey to ensure the foundation bearing capacity meets requirements. • Climate Factors: A reasonable drainage system should be designed considering wind, rain, snow loads, and seismic fortification requirements.

- Quality Control Key Points

- Welding and Connections: Weld quality and bolt tightness are critical control points and require third-party testing.

- Fireproofing and Insulation: Fire-retardant coatings or panels should be installed according to specifications, and the insulation layer should be designed reasonably to improve energy efficiency.

- Risk Contingency Plans

- Weather Delays: Contingency plans should be in place for severe weather.

- Supply Chain Risks: Ensure a stable supply of main materials such as steel to avoid work stoppages due to material shortages.

VI. Maintenance and Life Cycle Costs

- Long-Term Maintenance Plan

- Develop a regular inspection (especially for anti-corrosion layers and connection points) and cleaning and maintenance plan to extend the building’s lifespan.

- Sustainability Considerations

- Energy Efficiency: Utilize a photovoltaic system installed on the metal roof and design for natural lighting and ventilation to reduce operating costs.

- Recycling: Steel has a recyclability rate of over 90%; future dismantling and material reuse should be considered in the design. Conclusion

Successful metal construction projects begin with thorough planning and preparation. By clearly defining your needs, selecting appropriate materials and teams, strictly adhering to regulations, and focusing on long-term operation, you can not only ensure smooth project implementation but also maximize your return on investment, resulting in a safe, durable, and efficient building. Taking the time to do this homework before construction begins is the most important cornerstone for project success.

Friendly Reminder: This article is a general guideline. For specific projects, please consult a professional engineer and make decisions based on local conditions.

WARUM SDHJIE WÄHLEN?

Der Bau maßgeschneiderter Metallkonstruktionen ist unsere Spezialität.

Weitere Projekte