ما هو مبنى الهيكل الفولاذي؟

When we look up at the skyline of modern cities, those towering skyscrapers, magnificent bridges spanning rivers, or the imposing domes of stadiums, they often share a common supporting “skeleton”—a steel structure. Simply put, a steel structure building is a structure built primarily with steel as its load-bearing framework. It is not only an outstanding representative of modern engineering technology but also a key to humanity’s expansion of building height, span, and speed.

Core Material: A Combination of High Strength and Plasticity

The main component of a steel structure building is steel, primarily various types of steel (such as I-beams, H-beams, and angle steel), steel plates, and steel pipes. Compared to traditional reinforced concrete, steel has several significant advantages:

· High strength and light weight: The strength of steel is far greater than that of concrete. This means that under the same load, steel structural components have smaller cross-sections and are lighter in weight, making it possible to build taller and more agile buildings.

- Excellent plasticity and toughness: Steel can withstand large deformations without sudden fracture, exhibiting good seismic performance and effectively resisting dynamic loads such as earthquakes and strong winds.

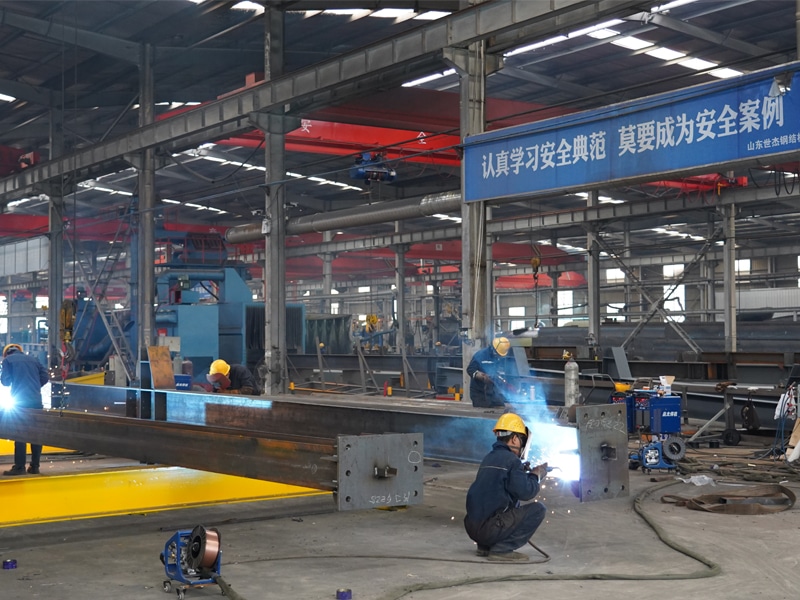

- Factory prefabrication with high precision: Steel components can be produced in standardized and precise factories and then transported to the site for assembly. This greatly improves building quality, shortens construction time, and reduces the impact on the site environment.

- Rapid construction, green and recyclable: On-site construction primarily utilizes prefabricated operations, minimizing weather impacts and significantly accelerating the process compared to traditional methods. After the building’s lifespan, steel can be nearly 100% recycled, aligning with sustainable development principles.

Main Structural Systems: From Skeleton to Space

Steel structures are not a single form; they evolve into different structural systems based on building function and aesthetic requirements:

- Frame structure: The most common form, consisting of rigidly connected steel beams and columns forming a three-dimensional frame that bears all vertical and horizontal loads. Widely used in high-rise office buildings, shopping malls, and residences.

- Spatial grid structure: Including space frames and shell structures, composed of numerous members connected according to certain rules to form a three-dimensional spatial system. It features reasonable stress distribution, high rigidity, and diverse shapes, and is commonly used for roofs of large stadiums, airport terminals, and exhibition centers.

- Tensioned Structures: Fully utilizing the tensile strength of steel, steel structures combine cables (steel cables) and membranes (fabric or thin films) to create highly expressive, lightweight roofs, such as stadium grandstand roofs and landscape features.

- Bridge Structures: In bridge engineering, steel structures, in the form of truss bridges, arch bridges, cable-stayed bridges, and suspension bridges, achieve astonishingly long spans.

Advantages and Challenges Coexist

Significant Advantages:

- Realizer of Large Spans and Super High-Rise Buildings: It liberates interior space, creating column-free, spacious halls and towering city landmarks.

- Synonymous with “Rapid Construction”: Construction time can be shortened by more than one-third, with faster capital turnover and significant overall benefits.

- Pioneer of Green Building: Materials are recyclable, construction pollution is low, and it aligns with the trends of industrialized construction and low-carbon development.

- Flexible Modification and Reinforcement: Easy to connect and modify, facilitating future functional changes of the building.

Challenges Faced:

- Fire Resistance: Although steel is non-combustible, its strength decreases sharply at high temperatures. Therefore, steel structures must be covered with fire-retardant coatings or panels to ensure they meet the specified fire resistance limits.

- Corrosion Resistance: Prone to rust when exposed to humid or corrosive environments, requiring regular anti-corrosion coatings or the use of special materials such as weathering steel.

- Stability and Buckling: Slender steel components may experience stability issues under pressure, requiring precise calculations and rational design.

- Cost Sensitivity: Fluctuations in steel prices significantly impact the total project cost.

Application Areas: The Ubiquitous Power of Steel

Steel structures have permeated every corner of modern society:

· Public Buildings: Stadiums (such as the Beijing “Bird’s Nest”), theaters, airports, high-speed rail stations, large exhibition centers.

· Commercial and Residential: High-rise office buildings, shopping malls, industrialized apartment buildings.

- Industrial Buildings: Heavy industrial buildings, power plants, petrochemical facilities, large warehouses.

- Infrastructure: Bridges, transmission towers, communication towers, offshore oil platforms.

- Emerging Fields: Modular buildings, data centers, logistics warehousing, emergency rapid-construction housing.

Classic Cases: The Poetic Expression of Steel

- Eiffel Tower (Paris, France): An engineering marvel of the late 19th century, its pure structural aesthetics demonstrate steel’s ability to shape urban symbols.

- Empire State Building (New York, USA): A prime example of early steel-structured skyscrapers, its efficient frame structure created the “world’s tallest building” at the time.

- National Stadium (“Bird’s Nest,” Beijing, China): Its intricate, giant steel woven structure showcases the ultimate expression of modern steel structures in both form and function.

- Burj Khalifa (Dubai, UAE): The world’s tallest building today, its core and outer frame employ a combination of high-performance reinforced concrete and steel structures.

Future Outlook: The Evolution of Intelligence and Green Development

Looking to the future, steel structure buildings are evolving towards greater intelligence, greener practices, and higher performance:

- Integration with Intelligent Construction: Combining BIM (Building Information Modeling), digital twins, and robotic automated processing and installation to achieve refined management throughout the entire lifecycle.

- Application of New Materials: The wider application of high-strength steel, weathering steel, stainless steel, and steel-concrete composite structures further enhances performance and durability.

- Modularization and Integration: Highly integrating structure, envelope, equipment, and finishes, manufacturing modules in factories allows for building houses like “building blocks,” revolutionizing building quality and efficiency.

- Responding to Dual Carbon Goals: As a representative of recyclable materials, steel structures will play a more central role in green buildings and near-zero energy buildings.

الخاتمة

In conclusion, هيكل فولاذي buildings are far more than just cold, hard steel forests. They are a combination of strength and beauty, a crystallization of rational calculation and artistic creativity. From the factories of the Industrial Revolution to the sky cities of the Information Age, steel structures have continuously pushed the physical and imaginative boundaries of human architecture. With its inherent strength, speed, and flexibility, it continues to shape more efficient, sustainable, and exciting living spaces for us. In the pursuit of taller, lighter, greener, and smarter buildings, steel structures will undoubtedly continue to play an indispensable role.