Your steel structure engineering expert

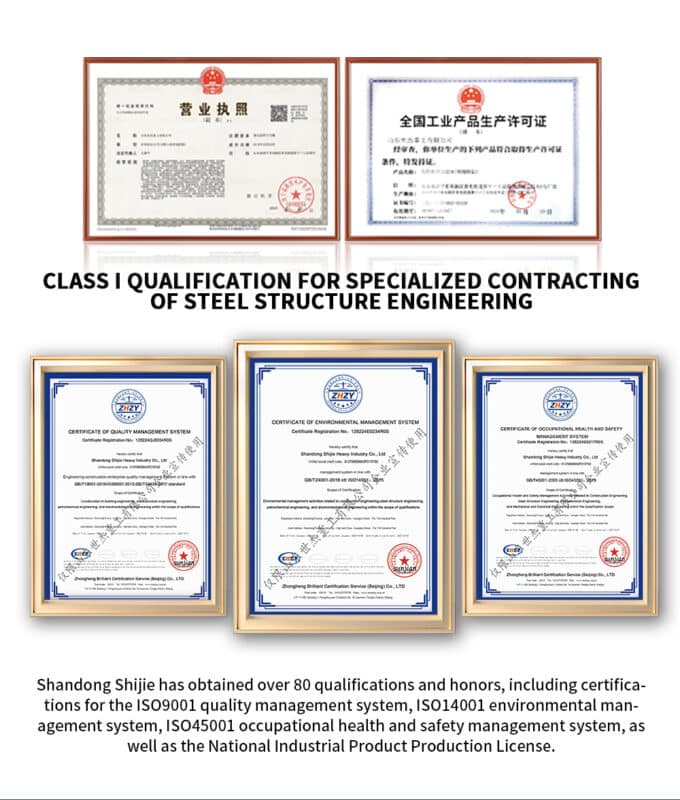

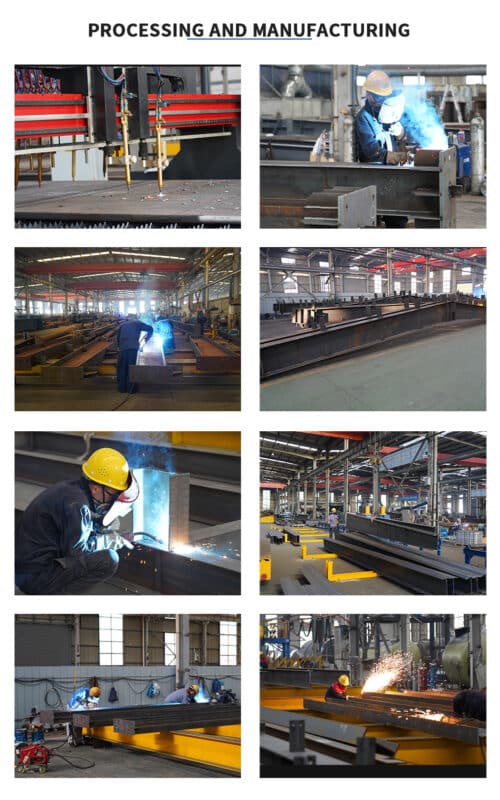

We are an international company specializing in steel structure construction and export, with over 15 years of experience in steel structure engineering. We have provided high-quality steel structure building solutions to more than 30 countries worldwide. Our company holds international quality system certifications and possesses integrated service capabilities encompassing design, manufacturing, construction, and export.

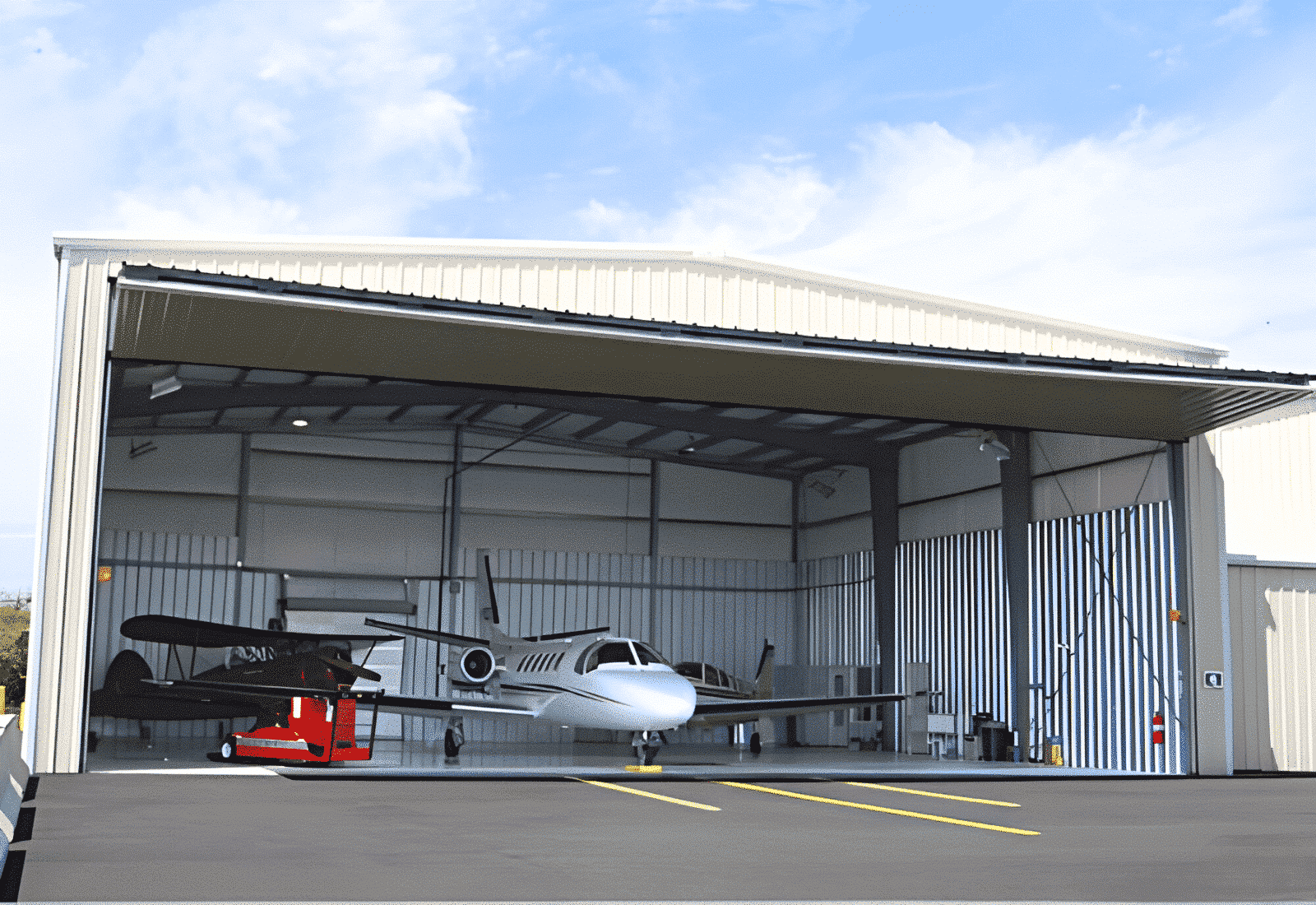

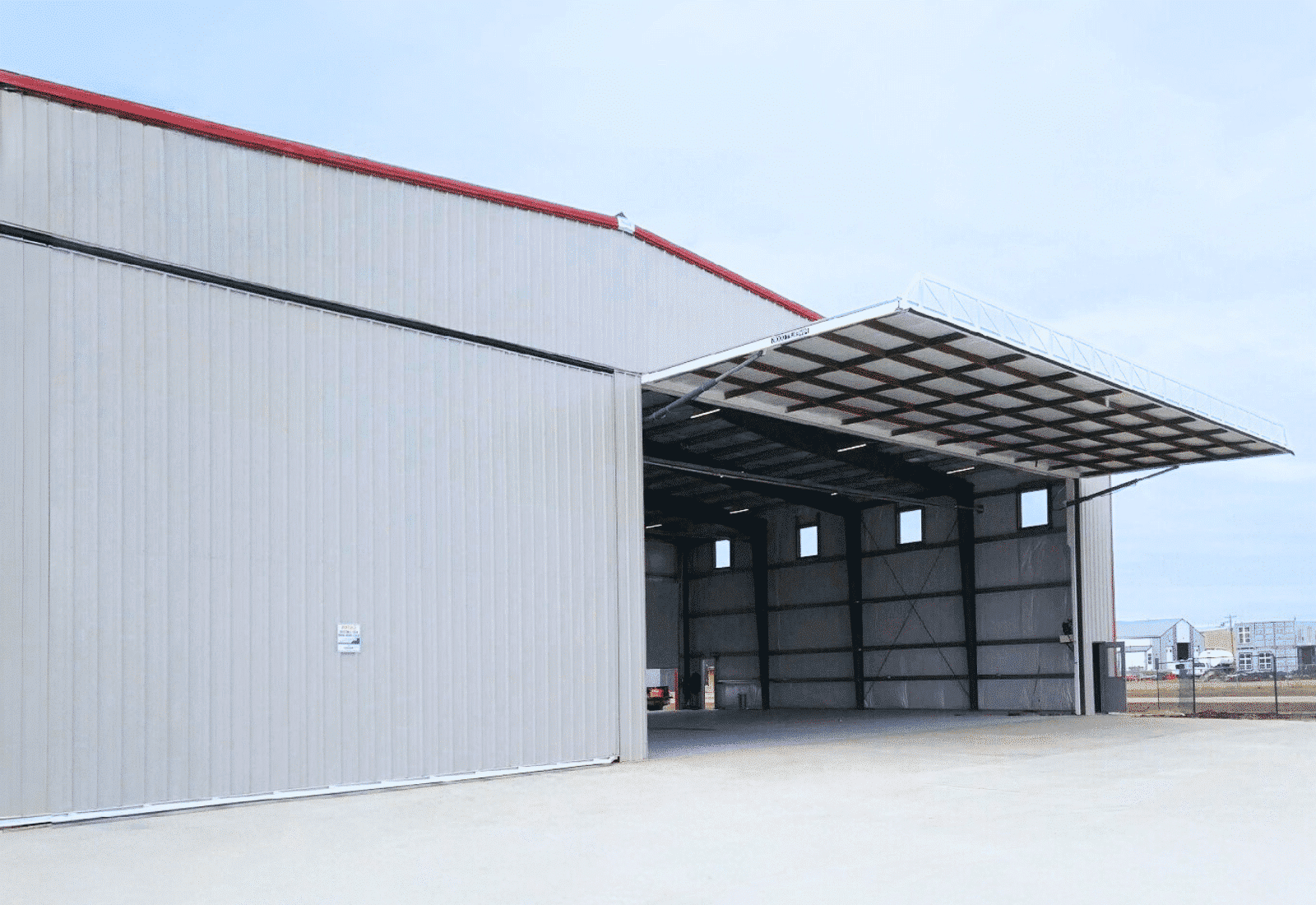

Modular Steel-framed Aircraft Hangar – Ideal for General Aviation & Maintenance Yards

Brand Name:

Model Number:

MOQ:

Price:

Delivery Time:

Payment Terms:

SHIJIE

SJ-1687

1000㎡

usd 80-200 per sqm

30 day

L/C,T/T

Detail information

Factory prefabrication + on-site assembly cuts construction period by 50%. Get a full breakdown of Modular Steel-framed Hangar advantages.

Core Features & Advantages

-

Superior Structural Strength: Constructed with high-grade Q235/Q355 steel, our hangars boast excellent load-bearing capacity, capable of withstanding heavy snow, strong winds (up to 120km/h), and seismic activities (up to magnitude 8). The rational steel frame design ensures stability even in extreme weather conditions, protecting your valuable aircraft and equipment.

-

Customizable Design: We offer full customization based on your specific requirements, including span (30m-100m+), height, length, and door type (sliding door, folding door, rolling door). Optional configurations such as insulation layers, ventilation systems, lighting fixtures, and fire protection equipment are available to meet different operational needs.

-

Quick Installation & Cost-Saving: Adopting a prefabricated production mode, all steel components are precision-manufactured in our factory and assembled on-site. This significantly shortens the construction period (30-60 days for a standard hangar) and reduces on-site labor costs. Compared with traditional concrete buildings, our steel hangars save up to 30% in overall construction costs.

-

Excellent Durability & Low Maintenance: The steel components undergo professional anti-corrosion treatment (galvanization or painting), ensuring resistance to rust, corrosion, and aging. The service life of our steel structure hangars can reach 50+ years with minimal maintenance, reducing long-term operational costs for customers.

-

Versatile Applications: Beyond aircraft storage and maintenance, our steel hangars are widely used for helicopter depots, drone testing facilities, aviation parts warehouses, and military aircraft shelters. The large internal space without columns provides maximum flexibility for equipment placement and operational activities.

Technical Specifications

|

Item

|

Specification

|

|---|---|

|

Steel Material

|

Q235B, Q355B (or as per customer requirements)

|

|

Span Range

|

30m – 100m+ (single-span or multi-span available)

|

|

Height Range

|

5m – 20m (customizable)

|

|

Wind Load Resistance

|

≤ 120km/h (can be enhanced for special regions)

|

|

Snow Load Resistance

|

≤ 1.2kN/㎡ (adjustable based on local climate)

|

|

Seismic Grade

|

≤ Magnitude 8

|

|

Service Life

|

50+ years

|

|

Installation Period

|

30 – 60 days (varies by size)

|

Our Service & Commitment

.

Vision & Mission

We are committed to providing safe, efficient, and environmentally friendly solutions for global customers through continuous technological innovation and exceptional product quality, driving industry progress and collectively creating a better future.

Core Values

We are guided by customer needs, deeply understand their scenarios, deliver products and service experiences that exceed expectations, and establish and maintain lasting partnerships.How to be a person | How to do things | How to do business | Pragmatic Innovation | Pursue excellence | Team Spirit

More products

Price Your Building

NDUSTRIALSTEEL BUILDINGS