What is Steel Structure?

A steel structure is a load-bearing framework composed of interconnected steel components, including beams, columns, and braces. It is designed to support heavy loads and resist external forces, demonstrating exceptional strength, durability, and versatility in industrial, commercial, and infrastructure projec

Common Structural Forms in Steel Construction

Steel structures can be configured in various forms, each tailored to meet different spatial, load-bearing, and architectural requirements. Below are the most widely used structural forms in modern construction.

Portal Frame Structure

A portal frame consists of rigidly connected steel beams and columns, forming a moment-resisting framework. This structural system is particularly suitable for low-rise industrial buildings that require large, open floor spaces without internal supports, such as warehouses, workshops, and hangars. Its shape resembles a gate, hence the term “portal.”

Key Advantages:

• Simplified geometry enables efficient load distribution under both vertical and lateral forces.

• Faster construction and lower costs compared to traditional concrete frames.

• Ideal for column-free layouts with minimal internal obstructions.

Typical Applications:

Industrial plants, storage facilities, agricultural buildings, and logistics warehouses.

FAQ – Is the portal frame suitable for seismic zones?

Yes. When properly designed and supplemented with adequate bracing, portal frame structures offer excellent seismic performance due to their inherent stiffness and joint continuity.

Multi-Story Steel Structure

This system utilizes vertical steel columns and horizontal steel beams to form a skeleton frame that supports floors and walls. It allows for highly flexible floor plans and vertical expansion, making it an ideal solution for complex urban buildings where space and functionality evolve over time.

Key Advantages:

• High redundancy ensures continued load redistribution even if certain components fail.

• Excellent resistance to lateral loads from wind and earthquakes.

• Enables adaptable, open interior spaces that can be reconfigured as needed.

Typical Applications:

Commercial towers, hospitals, universities, hotels, and multi-unit residential complexes.

FAQ – Why choose steel over concrete for high-rise buildings?

Compared to conventional concrete structures, steel allows for lighter foundations, faster installation, and more flexible interior layouts.

Steel Truss Structure

A truss is a triangular steel assembly composed of slender members connected at nodes. Trusses primarily carry loads through axial tension and compression, enabling long-span structures with high efficiency and minimal material usage. Their clean visual appearance also contributes to architectural expression.

Key Advantages:

• High stiffness-to-weight ratio allows for exceptionally long spans.

• Material-efficient solution for large open areas.

• Performs exceptionally well under dynamic or repetitive loads.

Typical Applications:

Bridges, airport hangars, sports stadiums, and exhibition halls.

FAQ – What is the main difference between a truss and a portal frame?

While both provide clear spans, trusses are lighter and more suitable for extra-large spans, whereas portal frames are simpler and typically faster to erect.

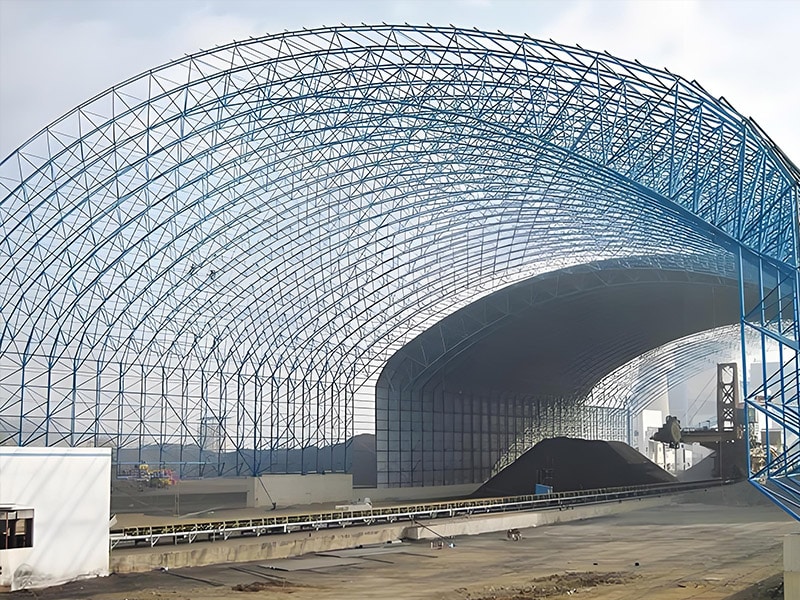

Space Frame Structure

A space frame is a three-dimensional structural system consisting of interconnected struts arranged in a geometric grid. Unlike planar trusses, space frames can withstand multi-directional loads, making them ideal for covering wide open areas with minimal support.

Key Advantages:

• Uniform distribution of loads across all axes.

• Modular units facilitate fast, precise factory prefabrication.

• Well-suited for wide-span roofs with few intermediate supports.

Typical Applications:

Airport terminals, convention centers, large retail halls, cultural venues, gas stations, canopies, and stadium roof structures.

FAQ – Are space frames structurally stronger than planar trusses?

In most cases, yes. Space frames distribute loads three-dimensionally, providing greater stability, stiffness, and reduced deflection over large spans.

Light Steel Framing Structure

This system uses cold-formed thin-walled steel sections to create lightweight yet strong and durable building frames. It is especially suitable for low-rise construction, enabling rapid assembly and modular prefabrication.

Key Advantages:

• Lightweight design facilitates transportation and quick on-site assembly.

• High dimensional accuracy supports prefabrication and BIM integration.

• Ideal for energy-efficient building envelopes with effective insulation.

Typical Applications:

Prefabricated houses, mobile offices, low-rise commercial units, temporary structures, and greenhouse frames.

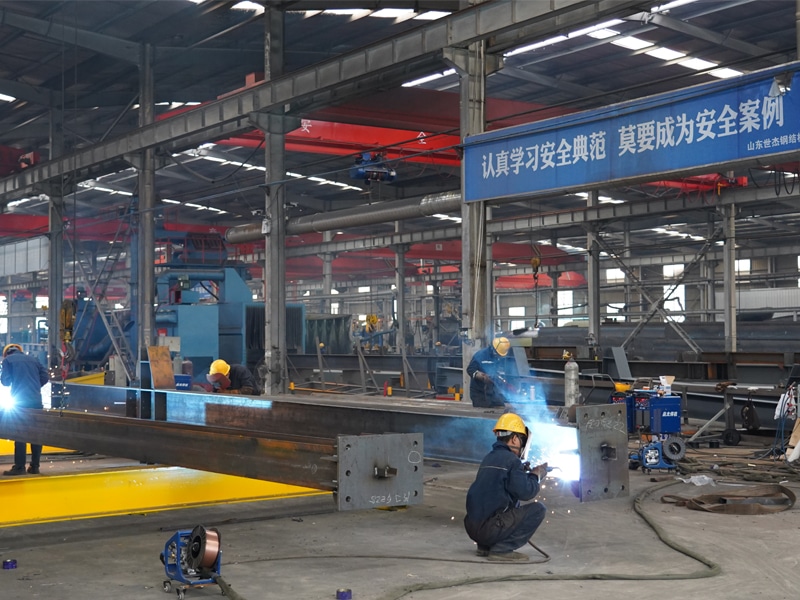

More projects