Guidelines for Steel Thickness Selection in Precast Metal Buildings

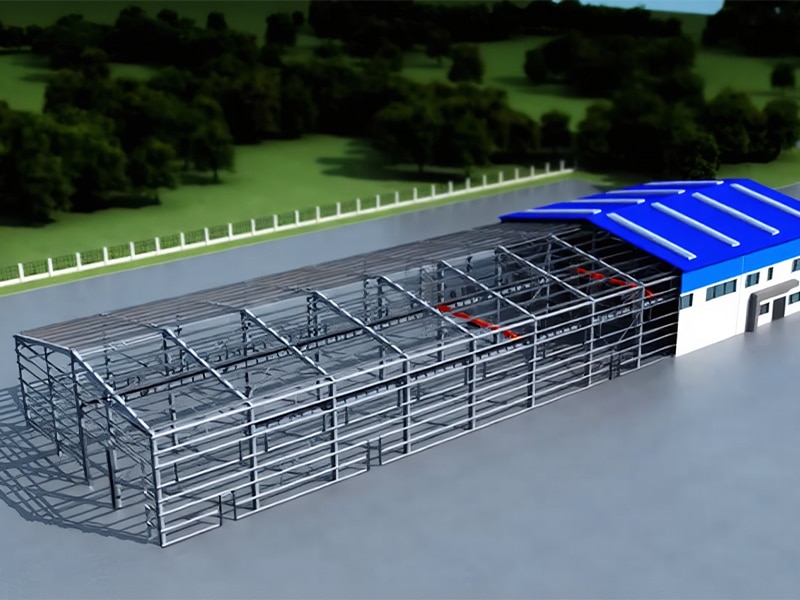

Precast metal buildings are widely used in industrial plants, warehousing facilities, and sports stadiums due to their advantages such as rapid construction, cost-effectiveness, and high durability. The selection of steel thickness directly affects the structural safety, service life, and economy of the building, making it a crucial aspect of the design process.

I. Main Factors Affecting Steel Thickness

- Building Use and Load Requirements

- Industrial Plants: Equipment weight, crane load, etc., must be considered.

- Warehouse Buildings: Cargo stacking load must be calculated.

- Sports Stadiums: The stability of large-span structures must be considered.

- Agricultural Buildings: Generally lighter loads, but wind and snow loads must be considered.

- Environmental Conditions

- Wind Load: Higher requirements in coastal and mountainous areas.

- Snow Load: Roof structures need to be strengthened in snowy areas.

- Earthquake Risk: Structural strength needs to be increased in high-seismic areas.

- Corrosive Environment: Corrosion prevention measures need to be considered in coastal and chemical industrial areas.

- Building Dimensions and Span

- The larger the span, the thicker the main structural steel needs to be.

- Increased building height requires stronger wind-resistant columns.

- Roof slope affects snow accumulation capacity and drainage requirements.

II. Reference Range for Steel Thickness in Various Parts

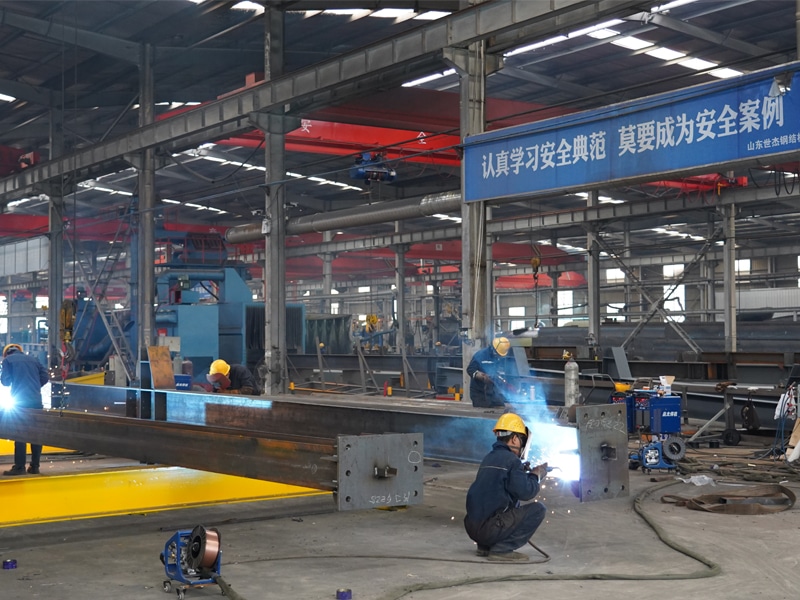

Main Structural Steel

- Main Steel Frame (Columns, Beams): Typically uses 3-12mm thick hot-rolled H-beams or welded H-beams. • Small buildings (span < 15m): 4-6mm

- Medium buildings (span 15-30m): 6-10mm

- Large buildings (span > 30m): 8-12mm or thicker

- Substructure (purlins, wall beams)

- C-shaped/Z-shaped cold-formed thin-walled steel: Typically 1.5-3.0mm

- Purlin spacing and span determine the specific thickness

Roofing and Wall Systems

- Roof panels: Typically 0.4-0.8mm

- Ordinary buildings: 0.5-0.6mm

- Industrial buildings: 0.6-0.8mm

- Areas requiring pedestrian access for maintenance: ≥0.8mm

- Wall panels: Typically 0.4-0.7mm

- Lower impact-prone areas: Can be thickened to 0.8-1.0mm

Connectors and Accessories

- Bolts, connecting plates, etc., are usually slightly thinner than the main structure but must meet strength requirements.

III. Design Process and Professional Advice

Scientific Design Process

- Load Calculation: Accurately calculate permanent loads, variable loads, and accidental loads.

- Structural Analysis: Perform stress analysis using professional software.

- Section Selection: Select an economical and reasonable section based on internal force results.

- Node Design: Ensure safe and reliable connections.

- Corrosion and Fire Protection Design: Determined based on environmental and usage requirements.

Professional Advice

- Avoid the “thicker the better” misconception: Excessive thickening increases costs and may alter the structural stress characteristics.

- Consider corrosion allowance: In corrosive environments such as coastal areas and industrial zones, a thickness increase of 0.5-1.0 mm is necessary.

- Emphasize overall balance: Avoid unfavorable designs such as “strong beams and weak columns.”

- Life cycle cost: Consider long-term costs such as maintenance and energy efficiency.

Precast Metal Buildings

Guidelines for Steel Thickness Selection in Precast Metal Buildings

IV. Frequently Asked Questions

Q: Can I decide the steel thickness myself?

A: No. The steel thickness must be determined by a registered structural engineer based on calculations and specifications. Changing it yourself may lead to safety hazards or violations of building codes.

Q: How to balance cost and safety?

A: Through optimized design rather than simple thinning. High-strength steel and optimized structural layout can be used to control costs while ensuring safety.

Q: What is the relationship between steel thickness and coating?

A: The coating (zinc plating, aluminum-zinc plating) mainly provides corrosion protection and does not affect the structural thickness calculation. In corrosive environments, both material thickness and coating quality must be considered.

V. Summary

Selecting the steel thickness for precast metal buildings is a highly specialized and systematic project; there is no single, universally applicable answer. The basic principles are:

- Compliance with standards: Strictly adhere to national and industry standards.

- Scientific calculations: Based on accurate load analysis and structural calculations.

- Comprehensive consideration: Balance safety, economy, durability, and functional requirements.

- Professional design: Engage a qualified professional team for design.

The final thickness should be determined by a structural engineer based on the specific project’s load conditions, usage requirements, and environmental factors. It is recommended that owners focus on the supplier’s design capabilities and compliance with standards when selecting a supplier, rather than simply comparing steel thickness figures.

Note: This document provides general guidance; please consult a professional structural engineer for specific projects.

More projects