Welded Ball Space Frames vs. Bolted Ball Space Frames: A Comprehensive Analysis of Structural Differences and Application Scenarios

In modern spatial structure engineering, steel space frames, with their superior spanning capacity, elegant architectural forms, and efficient load-bearing performance, are widely used in large-span buildings such as stadiums, exhibition halls, airport terminals, and industrial plants. Welded ball space frames and bolted ball space frames, as two mainstream forms of steel space frames, each have distinct technical characteristics and applicable scopes. This article will delve into the core differences between these two space frame structures in terms of structural principles, construction technology, mechanical properties, economy, and applicable scenarios, providing a reference for engineering design and selection.

I. Core Structure and Connection Principles

Welded ball space frames use hollow steel spheres as nodes. The ends of the members (usually steel pipes) are directly connected to the steel spheres through on-site welding, forming rigid joints. This connection method ensures that the axis of the members precisely intersects at the center of the sphere, resulting in direct force transmission and high node rigidity. Welded ball joints typically require precision pre-processing in the factory according to the number and angle of the members to ensure accurate on-site alignment.

Bolted ball space frames use solid steel balls as nodes, with high-strength bolt holes pre-drilled in the spheres. Conical heads or end plates are welded to the ends of the members, which are then fastened to the steel balls with high-strength bolts. This connection is a hinged node, where the members primarily bear axial forces, with minimal impact from bending moments. All bolted ball nodes are machined in the factory, enabling true “assembly-based” construction on-site.

II. Construction Technology and Quality Control

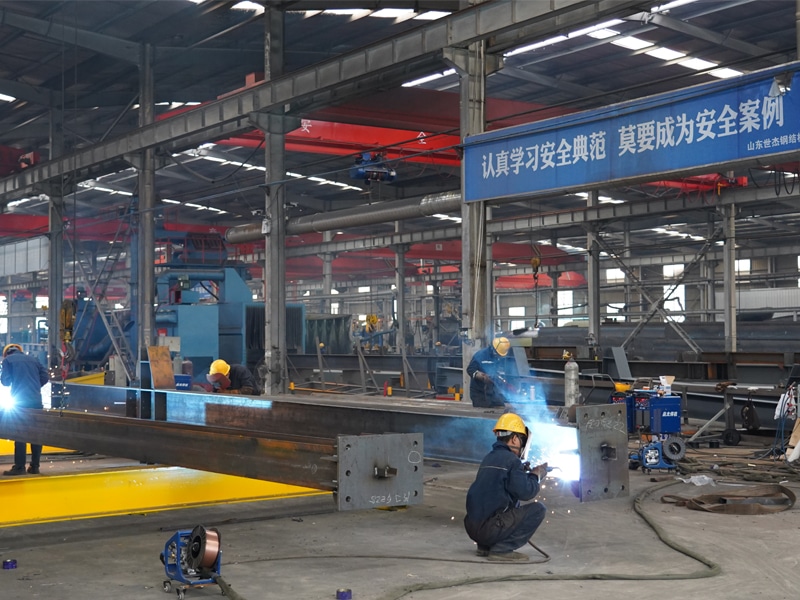

The core of welded ball space frame construction lies in on-site welding. The process includes: ground assembly of small units, high-altitude hoisting and positioning, measurement and calibration, and final welding and fixing. Quality control focuses on weld quality, requiring strict adherence to procedures such as welder certification, welding procedure qualification, and non-destructive testing (UT, RT) of welds. On-site welding is greatly affected by weather (wind, rain, low temperatures), demanding high standards of construction organization and management. However, due to the high rigidity of the nodes and good overall stability, the requirements for temporary reinforcement of the support system are relatively low.

The core of bolted ball space frame construction lies in high-precision assembly. The process is as follows: prefabricate all members and bolt balls in the factory → assemble on-site according to numbering → initial tightening → final tightening to the design preload. Key quality control points are bolt preload control and component machining accuracy. Calibrated torque wrenches or electric wrenches must be used, and bolt axial force must be checked regularly. Component machining errors must be extremely small, otherwise installation difficulties will result. Construction is largely unaffected by weather and is extremely fast, but requires extremely high accuracy in on-site measurement and layout.

III. Mechanical Properties and Structural Characteristics

From a structural analysis perspective, the differences between the two are significant:

· Node Stiffness: Welded ball nodes are close to rigid connections, capable of transmitting axial force, shear force, and bending moment, resulting in greater overall stiffness and better stability of the space frame. Bolted ball nodes are close to hinged connections, primarily transmitting axial force, and the structural analysis model is simpler.

· Load-bearing Performance: Due to the rigidity of the nodes, welded ball space frames have certain secondary bending moments in the members, placing higher demands on the load-bearing capacity of the nodes themselves and the members. Bolted spherical space frames primarily bear axial forces, resulting in more efficient material utilization and a calculation model that better matches actual conditions.

- Spatial Function: Welded spherical space frames exhibit stronger overall spatial synergy and superior ability to adjust to uneven and localized loads. Bolted spherical space frames are more sensitive to boundary conditions and support arrangement.

IV. Economic Efficiency and Project Cycle

Welded Spherical Space Frames:

- Advantages: Relatively lower steel consumption at nodes, eliminating the need for expensive high-strength bolts and complex machined spheres.

- Disadvantages: Significant on-site welding workload and high labor costs; substantial testing fees; long construction period; high investment in construction safety (high-altitude welding, fire prevention).

- Overall Economic Efficiency: The material savings may be more pronounced in projects with large spans, heavy loads, and complex shapes, but management costs are high.

Bolted Sphere Space Frame:

- Advantages: Extremely high degree of factory production (over 95%), stable quality; extremely fast on-site installation, shortening the construction period by 30%-50%; no open flame operations on-site, high safety; good conditions for civilized construction.

- Disadvantages: Larger steel consumption at nodes (solid spheres), high cost of high-strength bolts and machining.

- Overall Economic Efficiency: In projects with high standardization, moderate span, and tight schedules, although material costs are high, the overall economic benefits are often superior due to savings in construction time and management costs.

V. Typical Application Scenarios Comparison

Situations where welded sphere space frames are preferred:

- Ultra-large span structures: Such as stadiums and airport terminals with spans exceeding 100 meters, requiring extremely high overall rigidity and stability.

- Large dynamic or suspended loads: Industrial plants equipped with suspended cranes or large suspended equipment, or large public buildings with high pedestrian traffic prone to vibration. 3. Large and complex node loads: Large concentrated loads at nodes, or abnormal angles at member intersections, make reliable connections easier to achieve with welded spheres.

- Extremely complex architectural shapes: For non-standard shapes such as hyperboloids and freeform surfaces, welded sphere nodes offer greater spatial adaptability.

Situations where bolted sphere space frames are preferred:

- Standardized buildings with small to medium spans: Such as standard factories, warehouses, and commercial centers, fully leveraging their prefabrication and rapid assembly advantages.

- Projects with extremely tight deadlines: Such as emergency projects and renovation/expansion projects.

- Situations with limited on-site working conditions: Such as urban centers, chemical plant areas, and other areas where open flame operations are strictly prohibited.

- Structures requiring later disassembly or modification: Bolted connections allow for disassembly, leaving room for future modifications.

Conclusion and selection recommendations

The difference between welded sphere space frames and bolted sphere space frames essentially lies in the technical approach differences between rigid and hinged connections, on-site construction and factory prefabrication, and customization and standardization. Neither technology is inherently superior or inferior; the choice lies in suitability.

When selecting a technology for a project, a systematic weighing of factors is crucial:

First, consider the building’s functional and mechanical requirements: analyze span, load, dynamic characteristics, and building form.

Second, assess construction conditions and schedule: examine the site environment, construction season, schedule pressures, and safety management resources.

Finally, conduct a full life-cycle economic comparison: comprehensively calculate the costs of materials, processing, installation, testing, maintenance, and even future modifications.

Currently, the two technologies are showing a trend towards integration. For example, in large-scale projects, a “hybrid space frame” model is used, employing welded spheres in the core load-bearing areas and bolted spheres in the surrounding standard areas, combining the advantages of rigidity and rapid assembly. With advancements in digital design and robotic processing technologies, the gap in processing precision and construction efficiency between the two is narrowing, but a deep understanding of their core differences remains the cornerstone for making optimal engineering decisions.

More projects