steel structure splicing

1. Splicing of Steel Structures with Uniform Cross-Sections

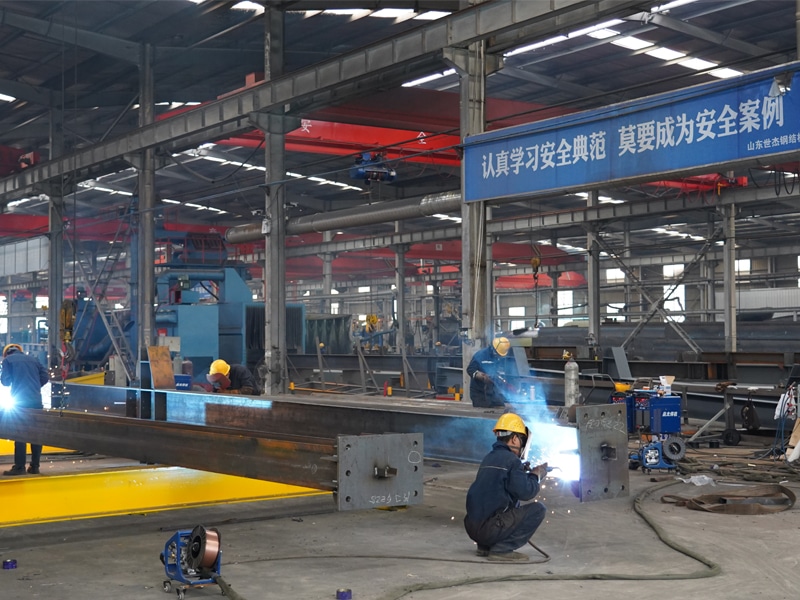

Factory Splicing of Steel Structures

Tension Members: Direct butt welding (Fig. a) or splice plates with fillet welds (Fig. b) may be used. For direct butt welding, the weld quality must meet Grade I or Grade II standards; otherwise, splice plates with fillet welds must be employed.

Compression Members: Direct butt welding (Fig. a) or splice plates with fillet welds (Fig. b) may be used.

When splice plates and fillet welds are adopted, the flanges and web of the member should be equipped with separate splice plates and welds to ensure direct and uniform force transmission, avoiding excessive stress concentration. When determining the width of the web splice plate, sufficient clearance must be reserved to facilitate electrode operation during longitudinal weld welding.

On-Site Splicing of Steel Structures

Tension Members: Splice plates may be added with high-strength bolts (Fig. c), or end plates may be added with high-strength bolts (Fig. d).

Compression Members: Welding may be used (Figs. e, f), or forces may be directly transmitted through bearing after planing the upper and lower contact surfaces (Figs. g, h). During welding, the upper part of the member should be pre-chamfered in the factory. The lower part (or both upper and lower parts) is equipped with positioning elements (channel steel or angle steel) to ensure proper alignment during welding. After planing the upper and lower contact surfaces, if forces are transmitted directly through bearing, a small number of welds and bolts should be added to prevent displacement. The splicing of tension and compression members should follow the principle of equal strength, meaning the splice materials and connectors should be capable of withstanding the maximum internal force of the fractured section.

2. Splicing of Steel Beams

Due to varying construction conditions, beam splicing methods are divided into factory splicing and on-site splicing.

Factory Splicing of Steel Structures

- To avoid weld concentration, the flange and web splicing positions should preferably be staggered.

- Butt welding is generally used for flange and web splice welds.

- For welds meeting Grade I and Grade II welding quality inspection standards, verification calculations are not required.

- For welds meeting Grade III welding quality inspection standards, verification calculations are required. If the weld strength is insufficient, inclined welding may be used. When θ satisfies tan θ ≤ 1.5, verification calculations are not required.

On-Site Splicing of Steel Structures

- During on-site splicing, the flange and web are typically disconnected at the same cross-section to facilitate segmented transportation (Fig. a). To allow some expansion and contraction of the flange plate during welding, thereby reducing welding residual stress, a length of approximately 500 mm may be left unwelded in the factory.

- As shown in Fig. b, appropriately staggering the flange and web splicing positions can prevent weld concentration at the same cross-section, although this may complicate transportation.

- For more critical riveted beams or large welded beams under dynamic loads, high-strength bolts are commonly used for on-site connections.

3. Connections Between Main Beams and Secondary Beams

Secondary Beams with Free Support

1) Overlapping Connection

Structure: Support stiffeners should be arranged at corresponding positions on the main beam to avoid excessive local pressure on the main beam web.

Characteristics: Simple structure, easy installation of secondary beams, but the main and secondary beam system occupies a larger net space.

Calculation: Generally, no calculation is required, and bolts are used only for fixing.

2) Side Connection

Structure: The secondary beam is connected to the side of the main beam, either directly to the main beam stiffener (Figs. a, b) or to short angle steel (Figs. c, d).

Characteristics:

- Fig. a: Connected via bolts to the stiffener, simple structure, easy installation, but one side of the secondary beam’s upper and lower flanges must be cut.

- Fig. b: On-site welded connection. Bolts are used only for temporary fixation, but welding at the end of the secondary beam web is inconvenient.

- Figs. c, d: Short angle steel is used for bolted or welded connections between the main and secondary beams. This requires cutting away part of the upper flange.

Calculation: - Figs. a, b: The required number of welds or bolts should be calculated based on the reaction force of the secondary beam. Considering the connection is not ideal, the reaction force should be increased by 20%–30%.

- Fig. c: When calculating bolt ①, the angle steel and secondary beam can be treated as a whole. Thus, bolt ① should withstand the combined action of the reaction force R and moment M = R·e. In contrast, bolt ② only withstands R. Alternatively, the angle steel can be considered part of the main beam. In this case, bolt ① only withstands R, while bolt ② should withstand the combined action of R and M = R·e.

- Fig. d: The calculation method is similar to Fig. c. Welds ① and ② also bear the combined action of R or R and M = R·e, respectively.

Continuous Secondary Beams

Freely supported beams overlap, but the secondary beam passes continuously through the main beam without disconnection. When splicing of the secondary beam is required, the splicing position can be set at a location with smaller bending moments. Bolts or welding are used to fix the main and secondary beams.

1) Overlapping Connection

Freely supported beams overlap, but the secondary beam passes continuously through the main beam without disconnection. When splicing of the secondary beam is required, the splicing position can be set at a location with smaller bending moments. Bolts or welding are used to fix the main and secondary beams.

2) Side Connection:

Structure: To ensure continuity of the two-span secondary beam with the main beam, connection plates must be provided on the upper and lower flanges.

- Fig. a: The secondary beam web is connected to the main beam stiffener via high-strength bolts. The lower flange connection plate is divided into two parts and welded on both sides of the main beam web.

- Fig. b: On-site installation with welded connection. The secondary beam is supported on the main beam’s bracket. The secondary beam’s upper flange is provided with a connection plate, and the lower flange connection plate is replaced by a support plate.

Calculation:

The support reaction is transmitted from the support to the main beam, while the upper and lower flanges withstand the negative moment at the end. The horizontal force decomposed from the moment M, F = M/h (where h is the secondary beam height), is transmitted by the connectors, cover plates, and top plates. F is used to calculate the cross-sectional dimensions and the connection of welds or bolts. To avoid overhead welding, the connection cover plate is narrower than the upper flange, and the tension plate is wider than the lower flange.

4. Beam-Column Connections

The following basic principles should be followed when designing connection joints:

- Safety and reliability. Force analysis should align as closely as possible with actual working conditions. The calculation diagram should match or approximate the actual connection state of the members. The connection should have a clear force transmission path and reliable structural guarantees.

- Ease of fabrication, transportation, and installation. Reduce joint types; allow for adjustment of splice dimensions; simplify construction operations as much as possible, such as avoiding overhead welding, erecting supports during installation, etc.

- Economic rationality. The most economical method is determined after careful consideration of factors such as materials, production, and construction, and should not be interpreted as merely saving steel.

Based on rotational stiffness, beam-column connections can be divided into three types: flexible connections (hinged connections), rigid connections, and semi-rigid connections.

More projects